Food Container Automated Production Solutions

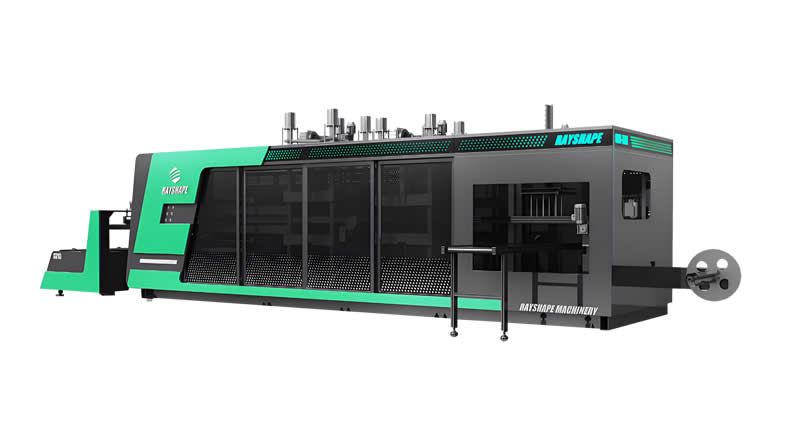

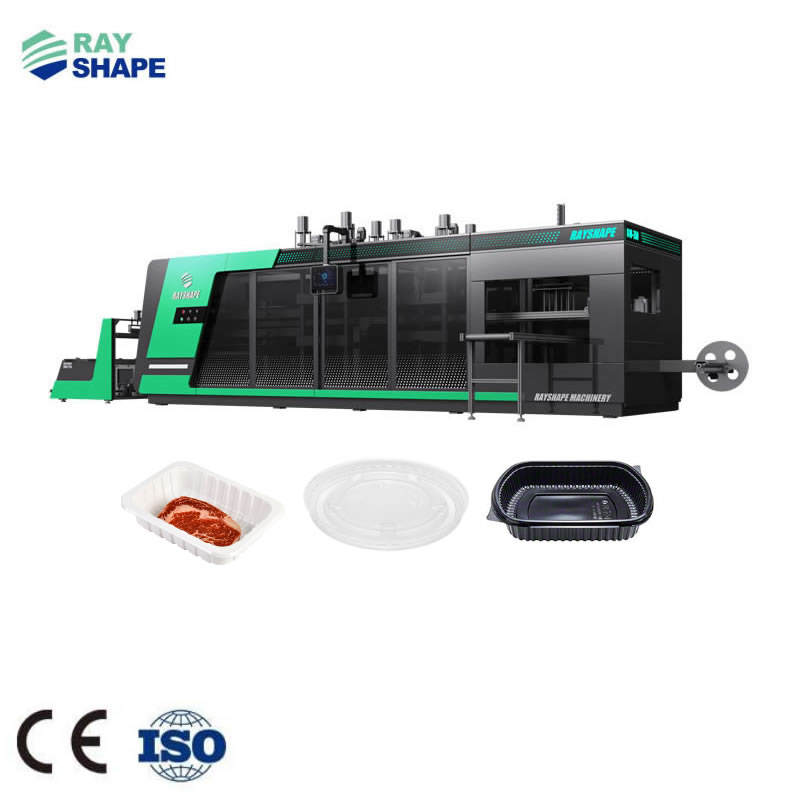

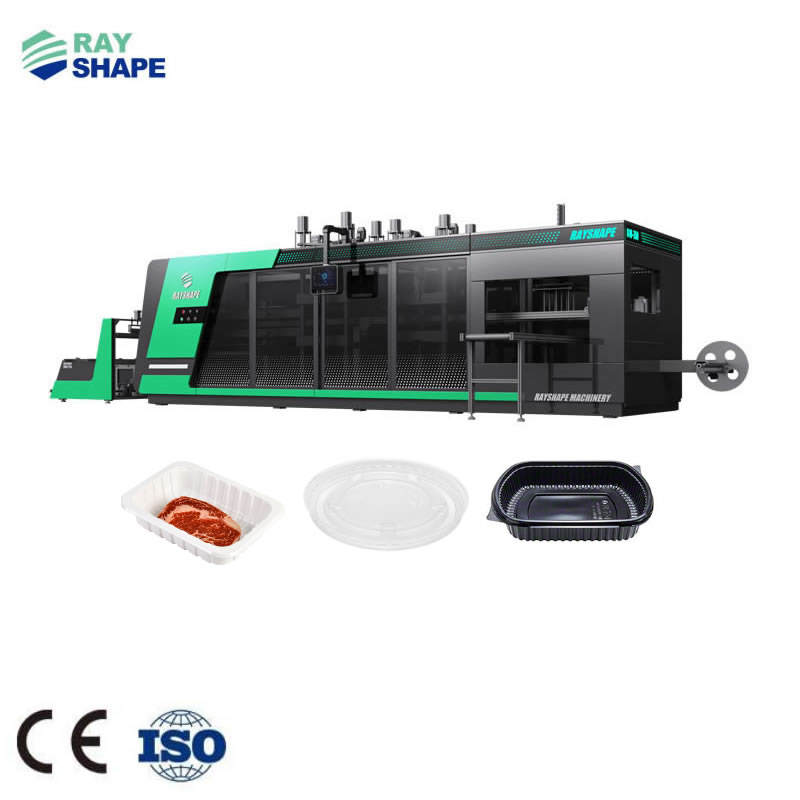

The Plastic Food Container Machine, a sophisticated variant of our multi-station thermoforming technology, sets a new benchmark in advanced packaging production. Specifically developed for the rigorous demands of the food industry, this Food Container Making Machine is expertly engineered to significantly reduce labor costs and deliver a stable, hygienic, and highly reliable output. This level of performance is crucial for manufacturers of disposable food service items.

These specialized systems, vital for the Food Container Thermoforming Machine application, are offered in highly automated three-station and four-station configurations. The four-station model is exceptionally efficient, featuring an integrated punching station essential for the clean, precise finishing of high-volume Plastic Food Containers. Our machines are indispensable for producing a vast array of disposable items, including plastic meal boxes, hinged containers, cup lids, and clear fruit packaging.

Rayshape’s machinery guarantees impressive speed and exceptional material flexibility, making it ideally suited for food contact materials like PP, PET, and PS. When processing PET sheets—often chosen for clarity and barrier properties—the machine achieves a maximum operating speed of up to 45 molds per minute. For PP sheets, commonly used for hot-fill and microwavable Plastic Food Containers, the maximum speed is typically up to 30 molds per minute. It is worth noting that actual output speed is intrinsically linked to product characteristics; deeper containers require a longer forming time for optimal results.

Designed with a brand-new control system and a future-oriented operating concept, this machinery guarantees sustained operational excellence. A key feature is the integrated parameter save function: since every specific Food Container Making Machine mold set requires unique operating parameters, once an engineer successfully optimizes a mold’s settings in the factory, these parameters are permanently stored. Restarting production with that mold is streamlined—simply press 'start,' and the machine will automatically recall and execute the saved, proven production settings.

These specialized systems, vital for the Food Container Thermoforming Machine application, are offered in highly automated three-station and four-station configurations. The four-station model is exceptionally efficient, featuring an integrated punching station essential for the clean, precise finishing of high-volume Plastic Food Containers. Our machines are indispensable for producing a vast array of disposable items, including plastic meal boxes, hinged containers, cup lids, and clear fruit packaging.

Rayshape’s machinery guarantees impressive speed and exceptional material flexibility, making it ideally suited for food contact materials like PP, PET, and PS. When processing PET sheets—often chosen for clarity and barrier properties—the machine achieves a maximum operating speed of up to 45 molds per minute. For PP sheets, commonly used for hot-fill and microwavable Plastic Food Containers, the maximum speed is typically up to 30 molds per minute. It is worth noting that actual output speed is intrinsically linked to product characteristics; deeper containers require a longer forming time for optimal results.

Designed with a brand-new control system and a future-oriented operating concept, this machinery guarantees sustained operational excellence. A key feature is the integrated parameter save function: since every specific Food Container Making Machine mold set requires unique operating parameters, once an engineer successfully optimizes a mold’s settings in the factory, these parameters are permanently stored. Restarting production with that mold is streamlined—simply press 'start,' and the machine will automatically recall and execute the saved, proven production settings.

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版