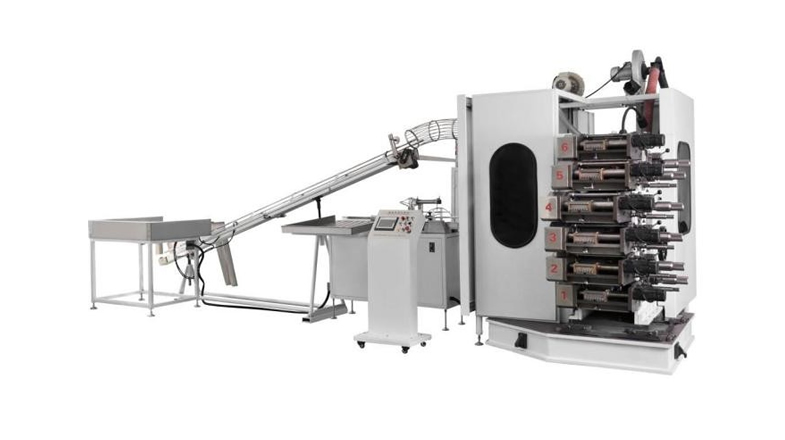

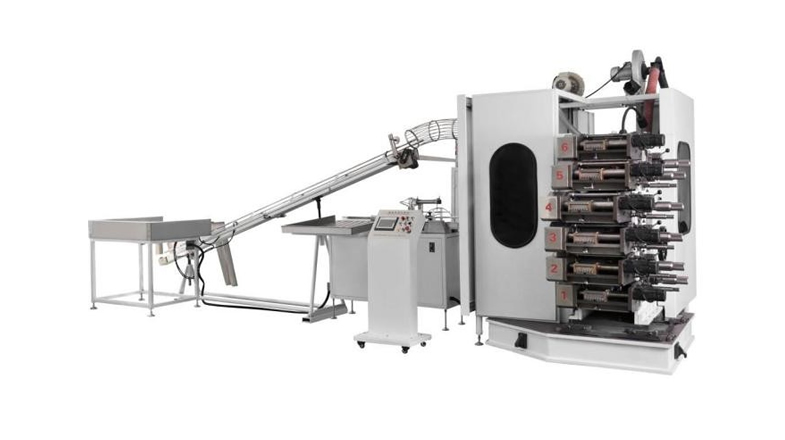

Six Color Printing Machine

INTRODUCTION

PRODUCTS RANGE

FEATURES AND ADVANTAGES

2, Easy adjustable separator of cup feeding drive to the printer, which operate fluently.

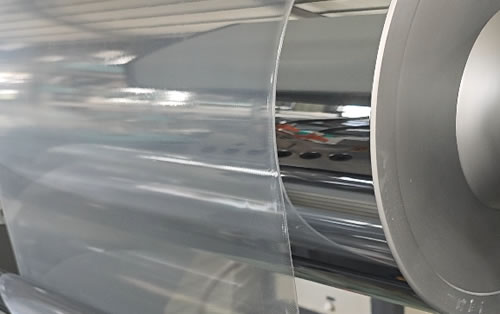

3, The roll gearbox can be automatic adjust the distance, ensure it is no shadow of cup surface.

4, The printing plate has specialized punch,which can be aligned accurately, quickly and operated easily.

5, Replacement of mould core or cup mould is convenient and fast.

6, Inspect function for problem cup by corona.

7, Printed articles sampling inspection function when working

8, Automatic counting by servo motor is more accurate, more easy to collect cup

9, Can be drive rubber model of transfer printing automatic.

10, Two motors two inverters to control printing system.

SPECIFICAITON

|

Model |

GC- 6-180 |

|

Max Printing Depth |

158 mm |

|

Cup depth |

50-180 mm |

|

Max cup body slope |

5-12 degree |

|

Max. Printing Speed |

150-330 cups/min ( shall be according to your cup size, material )

|

|

Cup material |

PP/ PS/ PET/ PLA/ HDPE |

|

Cup Rim Dia. |

Dia.40--180 mm |

|

Main motor total power (two motor ) |

8 kw |

|

UV Curing power |

6 kw |

|

Total power |

21 kw |

PARTNER BARANDS

Product Ordering

Please fill in the following information

Recommended Printing Machine

No recommended products available

Printing Machine Video

Printing Machine News

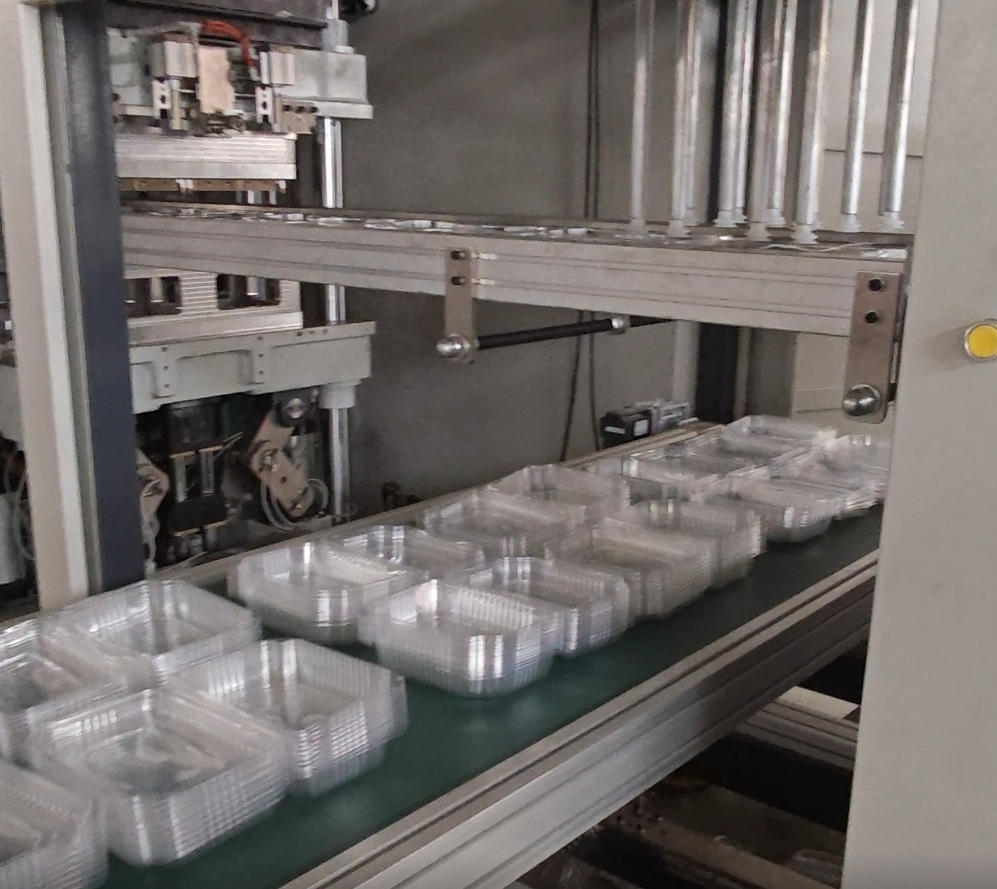

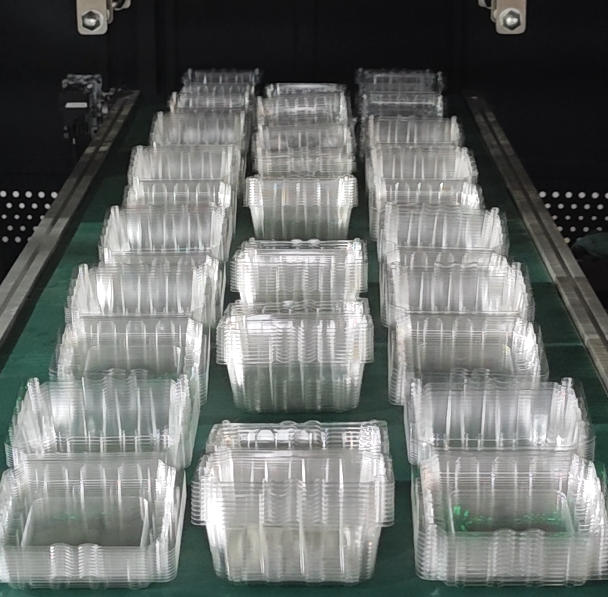

Advanced Fruit box making machine for International Exports

International fruit exports require high-quality packaging, and the Advanced Fruit box making machine from Wenzhou Rayshape Machinery Co., Ltd. is the perfect solution. Based in Wenzhou, our enterpris...

Cup Making Machine High-Speed Solutions

Modern cup making machines achieve unprecedented throughput rates of 80 cups/second through synchronized 32-station rotary systems processing PP, PET and PLA sheets from 200-1200 thickness. Material d...

Advanced Plastic Container Machine for Modern Food Factories

Modern food factories require advanced technology, and Wenzhou Rayshape Machinery Co., Ltd. provides it with our Plastic Container Machine. Located in the coastal city of Wenzhou, our enterprise is a ...

The Rayshape Plastic Container Thermoforming Machine

In the fast-paced world of industrial packaging, efficiency and stability are the cornerstones of a successful production line. Wenzhou Rayshape Machinery Co., Ltd., a premier subsidiary of the Ele...

Standardized Production for Seedling Trays and Nursery Plates

Wenzhou Rayshape Machinery Co., Ltd., a member of Elemotion Group, specializes in standardized production solutions with our Plastic Thermoforming Machine. Based in Pingyang County, Wenzhou, our ma...

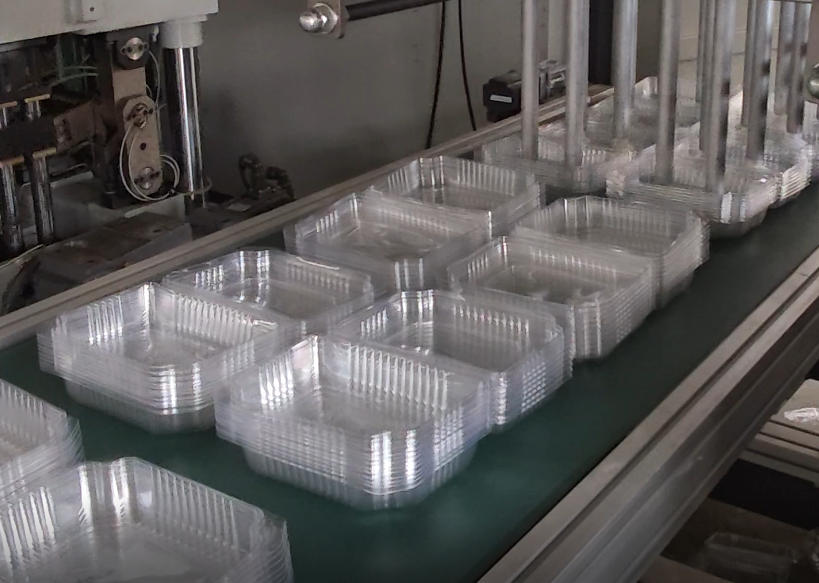

Advanced Vertical Stacking for Burr Free Plastic Trays

Cleanliness and organization are essential for food-grade packaging. Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, features a unique vertical stacking concept in our Plasti...

Analysis of Thermoforming Process and Industrial Practice of RAYSHAPE

The essence and advantages of thermoforming process Thermoforming is an advanced manufacturing process that heats the pre-extruded plastic sheet to a plastic state, forms it into a specific shape thr...

Durable Food Box Machine for Professional Catering Supplies

The professional catering market relies on the Durable Food Box Machine from Wenzhou Rayshape Machinery Co., Ltd. As a subsidiary of Elemotion Group, our company is dedicated to the development of hig...

High Efficiency Plastic Thermoforming Equipment for Industrial Use

Wenzhou Rayshape Machinery Co., Ltd. continues to redefine industrial standards with our High Efficiency Plastic Thermoforming Equipment. As a subsidiary of Elemotion Group, our mission is to provide ...

Versatile Plastic box forming machine for Retail and Catering

Wenzhou Rayshape Machinery Co., Ltd. provides a Versatile Plastic box forming machine that serves both the retail and catering sectors. As a subsidiary of Elemotion Group, we are located in the coasta...

Automatic Multi-station Thermoforming by Rayshape

Automatic Multi-station Thermoforming by Rayshape In high-volume manufacturing, efficiency is everything. The Automatic Multi-station Thermoforming Machine represents the pinnacle of this ...

Professional Pet Thermoforming Machine for High Volume Output

High-volume production requires the Professional Pet Thermoforming Machine from Wenzhou Rayshape Machinery Co., Ltd. Our company, a proud member of the Elemotion Group, specializes in high-end, highly...

Plastic Sheet Extruder Integration with Thermoforming Equipment

For a complete production solution, Wenzhou Rayshape Machinery Co., Ltd. offers the Plastic Sheet Extruder designed to work seamlessly with our thermoforming equipment. Based in Wenzhou and part of...

High Stretch and Shallow Stretch Versatility in Rayshape Machines

Different plastic products require different stretching techniques, and the Plastic Thermoforming Machine from Wenzhou Rayshape Machinery Co., Ltd. handles them all. A subsidiary of Elemotion Group...

Precision Cup Making Machine for Fast Food Beverage Industry

The fast food beverage industry demands high-speed precision, and the Cup Making Machine from Wenzhou Rayshape Machinery Co., Ltd. delivers exactly that. As a subsidiary of Elemotion Group in Wenzh...

Multi Station Plastic Thermoforming Equipment for Reliable Output

Reliability is the hallmark of the Multi Station Plastic Thermoforming Equipment from Wenzhou Rayshape Machinery Co., Ltd. A member of the Elemotion Group, our company is based in Pingyang County, ...

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版