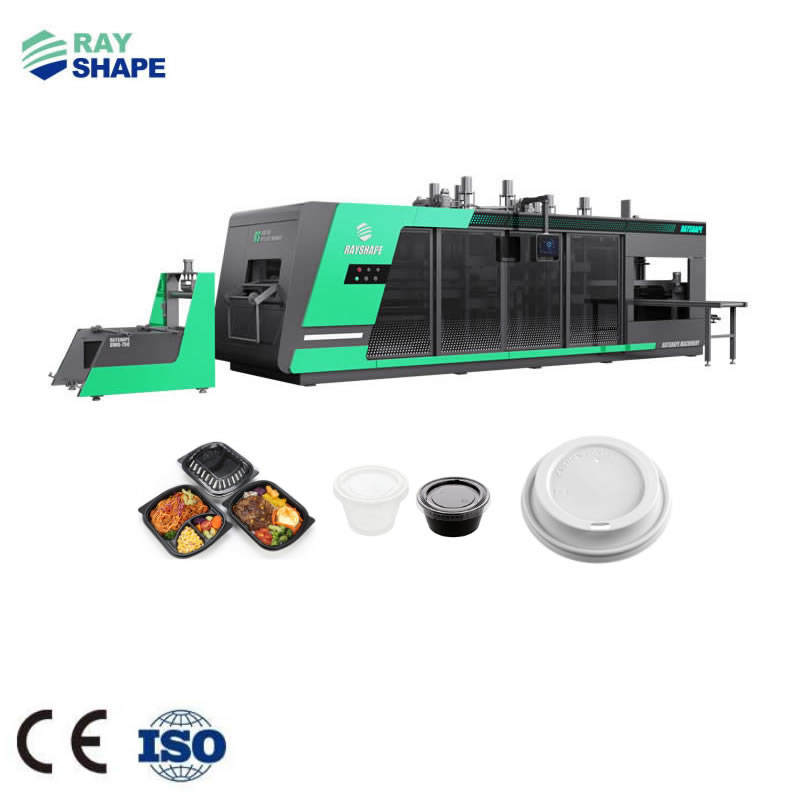

Cup Lid Automated Production Solutions

The Plastic Cup Lid Machine, a specialized version of our multi-station thermoforming technology, represents a significant engineering advancement tailored for the intricate demands of lid production. Developed specifically to address the challenges of high-volume, thin-gauge manufacturing, this equipment is expertly engineered to reduce labor costs while ensuring a stable, reliable output of perfectly formed cup lids.

These highly automated systems are commonly offered in three-station and four-station configurations. Our four-station model, featuring an essential integrated punching station, offers superior efficiency and precision critical for clean, accurate cutting of cup lid perimeters and vent holes. This dedicated Cup Lid Thermoforming Machine is essential for manufacturing a wide range of disposable items, including various sizes of cup lids, as well as egg trays, plastic meal boxes, and fruit packaging boxes.

Our Cup Lid Making Machine demonstrates impressive speed and excellent material flexibility, crucial for lid stock. It is optimally suited for processing materials such as PP, PET, and PS. When running thin-gauge PET sheets—ideal for clarity and rigidity—the maximum operating speed can reach up to 45 molds per minute. For PP sheets, the maximum speed is typically up to 30 molds per minute. It is vital to note that actual operating speed is influenced by factors like product depth (lid complexity) and sheet thickness; shallower lids can maximize speed.

Built on a brand-new design concept and a future-oriented control system, this specialized Plastic Cup Lid Machine guarantees operational excellence. Recognizing that each distinct cup lid mold set requires unique operating parameters, we have integrated a parameter save function within the equipment program. Once an engineer successfully debugs and optimizes a specific lid mold in the factory, those precise settings are permanently saved. Resuming production with that exact mold is effortless: simply click 'start,' and the machine will automatically execute the previously stored, proven parameters.

These highly automated systems are commonly offered in three-station and four-station configurations. Our four-station model, featuring an essential integrated punching station, offers superior efficiency and precision critical for clean, accurate cutting of cup lid perimeters and vent holes. This dedicated Cup Lid Thermoforming Machine is essential for manufacturing a wide range of disposable items, including various sizes of cup lids, as well as egg trays, plastic meal boxes, and fruit packaging boxes.

Our Cup Lid Making Machine demonstrates impressive speed and excellent material flexibility, crucial for lid stock. It is optimally suited for processing materials such as PP, PET, and PS. When running thin-gauge PET sheets—ideal for clarity and rigidity—the maximum operating speed can reach up to 45 molds per minute. For PP sheets, the maximum speed is typically up to 30 molds per minute. It is vital to note that actual operating speed is influenced by factors like product depth (lid complexity) and sheet thickness; shallower lids can maximize speed.

Built on a brand-new design concept and a future-oriented control system, this specialized Plastic Cup Lid Machine guarantees operational excellence. Recognizing that each distinct cup lid mold set requires unique operating parameters, we have integrated a parameter save function within the equipment program. Once an engineer successfully debugs and optimizes a specific lid mold in the factory, those precise settings are permanently saved. Resuming production with that exact mold is effortless: simply click 'start,' and the machine will automatically execute the previously stored, proven parameters.

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版