Innovative plastic molding machines drive future manufacturing

In the wave of global manufacturing intelligence and customization, plastic thermoforming technology plays a vital role. Rooted in Pingyang, Wenzhou, Zhejiang, Wenzhou Ruisu Machinery Co., Ltd. has become the core force leading the development of thermoforming equipment with its continuous innovation drive and deep industry accumulation.

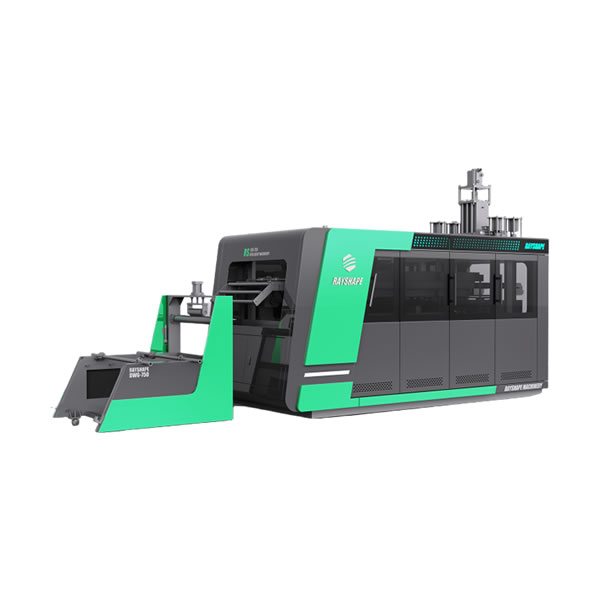

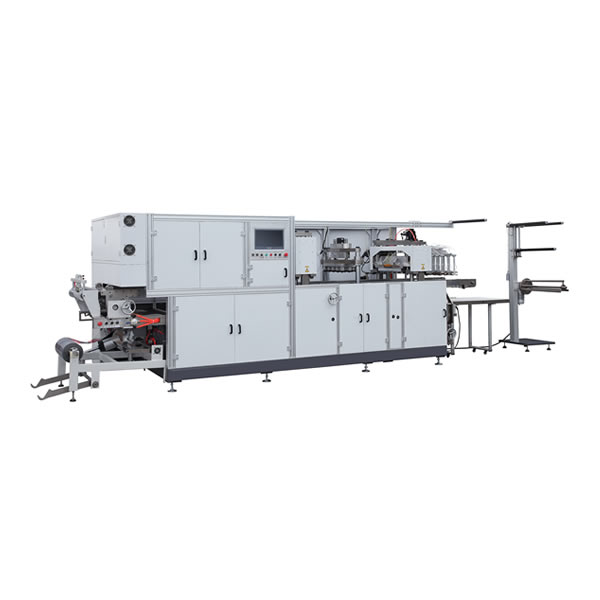

Ruisu is well aware of the differentiated needs of customers in different application scenarios. Relying on the leading R&D institutions in the domestic industry, the company has continuously optimized and upgraded its full range of products, from precise fully automatic multi-station thermoforming machines, RS series main machines to efficient and stable RS series single/double-layer and PET special sheet extruders. The technical team has devoted itself to research and developed models with higher precision and stricter sanitary protection for the food packaging field, ensuring the safety and consistency of the packaging materials; for the rigorous pharmaceutical industry, it has created special equipment that meets the requirements of high cleanliness and operational stability. More than ten years of technical accumulation and multiple patent achievements are a strong endorsement of the significant leap in the quality of Ruisu products.

Innovation is not a closed-door process. Ruisu actively cooperates with universities and research institutions, absorbs cutting-edge technology concepts, continuously integrates new materials, new processes, and intelligent elements into equipment design, and promotes continuous improvement in production efficiency and product quality. This market-oriented, technology-based innovation strategy ensures that Ruisu always stands at the forefront of industry development, providing customers with future-oriented thermoforming solutions, and "striving to innovate for the benefit of customers."

From providing stand-alone equipment to building a complete production line of raw material extrusion-thermoforming, Ruisu interprets the power of China's intelligent manufacturing with continuous technological breakthroughs, driving global partners towards a more efficient, smarter, and more reliable manufacturing future.

Ruisu is well aware of the differentiated needs of customers in different application scenarios. Relying on the leading R&D institutions in the domestic industry, the company has continuously optimized and upgraded its full range of products, from precise fully automatic multi-station thermoforming machines, RS series main machines to efficient and stable RS series single/double-layer and PET special sheet extruders. The technical team has devoted itself to research and developed models with higher precision and stricter sanitary protection for the food packaging field, ensuring the safety and consistency of the packaging materials; for the rigorous pharmaceutical industry, it has created special equipment that meets the requirements of high cleanliness and operational stability. More than ten years of technical accumulation and multiple patent achievements are a strong endorsement of the significant leap in the quality of Ruisu products.

Innovation is not a closed-door process. Ruisu actively cooperates with universities and research institutions, absorbs cutting-edge technology concepts, continuously integrates new materials, new processes, and intelligent elements into equipment design, and promotes continuous improvement in production efficiency and product quality. This market-oriented, technology-based innovation strategy ensures that Ruisu always stands at the forefront of industry development, providing customers with future-oriented thermoforming solutions, and "striving to innovate for the benefit of customers."

From providing stand-alone equipment to building a complete production line of raw material extrusion-thermoforming, Ruisu interprets the power of China's intelligent manufacturing with continuous technological breakthroughs, driving global partners towards a more efficient, smarter, and more reliable manufacturing future.

language

language