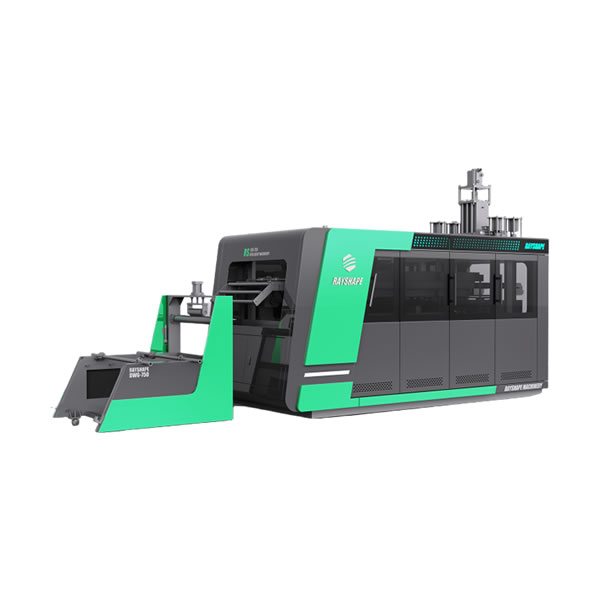

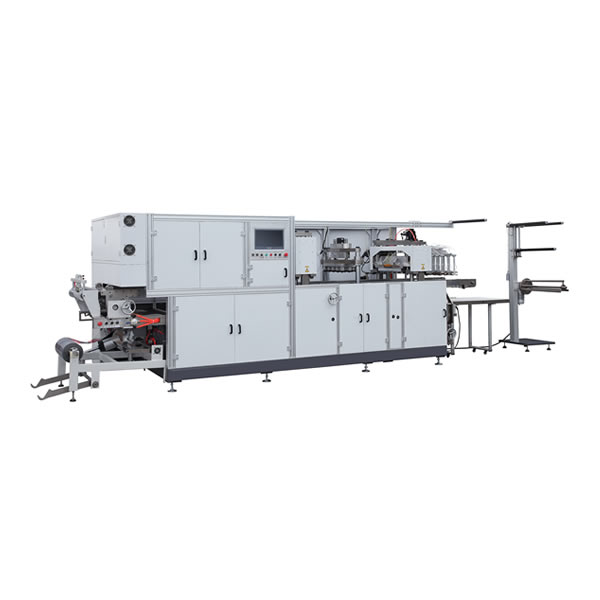

Thermoforming Machine: The Backbone of Modern Packaging

The thermoforming machine stands as a cornerstone in contemporary manufacturing, transforming plastic sheets into precise 3D shapes through controlled heating and forming processes. This equipment employs infrared heaters to uniformly heat thermoplastic sheets to their pliable state before draping them over molds. Using vacuum pressure or mechanical force, it creates products ranging from medical trays to automotive components. Modern thermoforming machines incorporate energy-recovery systems that reduce power consumption by 30% compared to traditional models, while their modular designs accommodate rapid mold changes for small-batch production. The versatility of thermoforming machines allows them to process diverse materials including PET, HIPS, and biodegradable PLA, making them indispensable for sustainable packaging solutions. With throughput capacities up to 2,000 cycles per hour, these machines enable cost-efficient mass production while maintaining ±0.15mm dimensional accuracy. As industries increasingly adopt Industry 4.0 principles, thermoforming machines now feature IoT sensors for predictive maintenance and cloud-based production monitoring.

language

language