Sheet Extruder

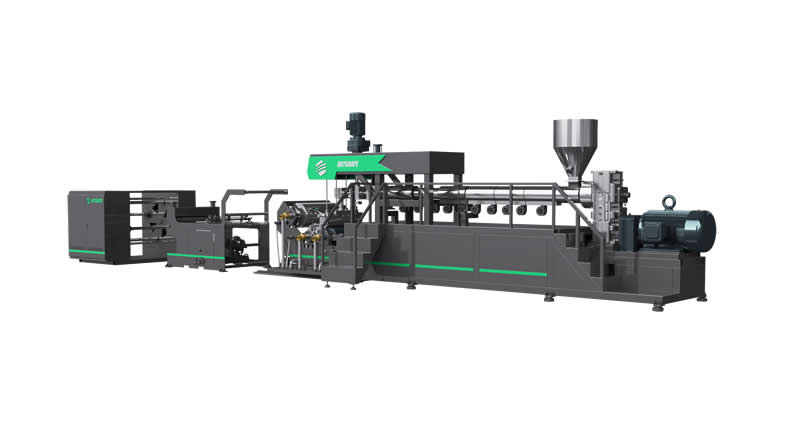

plastic sheet extruder-120-1000

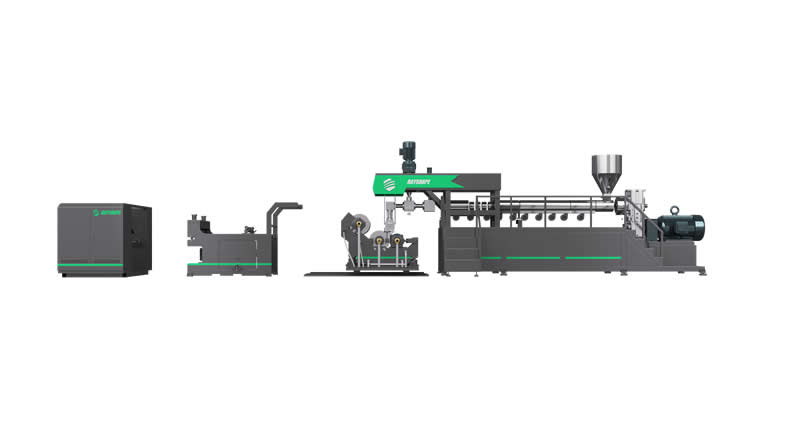

plastic sheet extruder-130-1000

Advanced Plastic Sheet Extruders by Wenzhou Rayshape

In the dynamic world of plastic manufacturing, every final product—from a meticulously formed cup to a protective blister pack—begins with a single, foundational component: a high-quality plastic sheet. The machine responsible for this critical first step is the plastic sheet extruder, a cornerstone of modern industrial production. At Wenzhou Rayshape Machinery Co., Ltd., we have elevated this technology to an art form. We specialize in producing sophisticated, high-performance plastic sheet extruders that not only meet but exceed the demanding standards of a global market, serving as the perfect complement to our comprehensive suite of forming machines.

Wenzhou Rayshape Machinery Co., Ltd.: A Foundation of Innovation

Nestled in the scenic coastal city of Pingyang County, Wenzhou, Zhejiang, Wenzhou Rayshape Machinery Co., Ltd. is a beacon of innovation and excellence. As a proud subsidiary of the esteemed Elemotion Group, our company is built on a foundation of robust R&D, strong operational capabilities, and unwavering commitment to customer satisfaction. We are located at No. 19, East Section of Pinghai Avenue, Binhai New Area, an ideal hub for our integrated operations which encompass mechanical and software R&D, production, marketing, and after-sales service.

Our journey began in 2021 with Elemotion’s strategic investment in Wuhu Youhe Automation Technology Co., Ltd. This marked the starting point of a transformative path that led to our official rebranding as Wenzhou Rayshape Machinery Co., Ltd. in 2025, now wholly owned by Wenzhou Elemotion Holdings. This legacy and our solid financial backing have empowered us to dedicate ourselves to the development of high-end, energy-efficient, and highly automated equipment.

Our diverse product portfolio—which includes Thermoforming Machines, Blister Machines, Cup Making Machines, Bowl Making Machines, Fully Automatic Thermoforming Machines, and Multi-station Thermoforming Machines—is rooted in the fundamental quality of the plastic sheets we produce. It is in this context that our plastic sheet extruder takes center stage as a vital part of our integrated ecosystem.

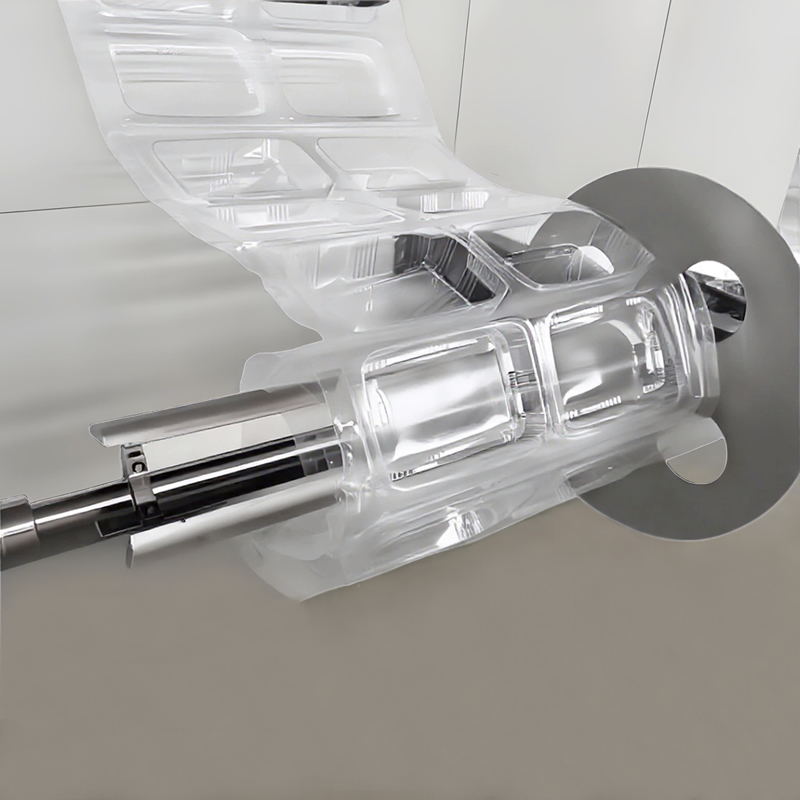

The Crucial Role of Plastic Sheet Extrusion

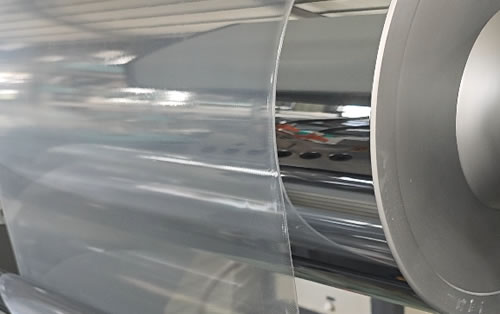

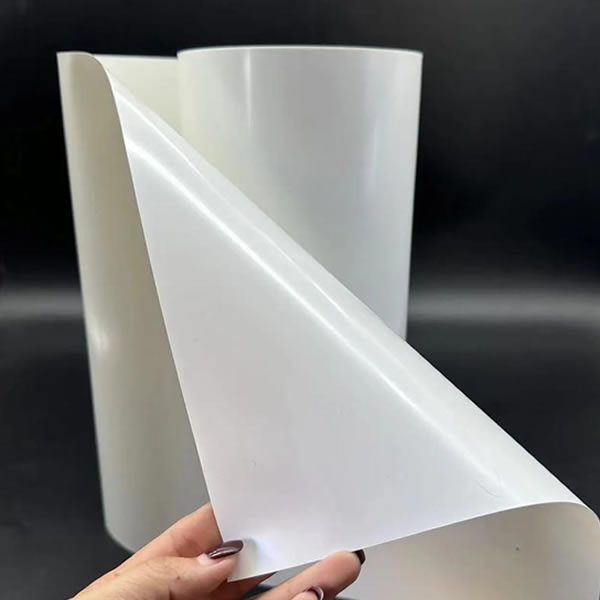

The importance of a high-performance plastic sheet extruder cannot be overstated. It is the machine that transforms raw plastic pellets into a continuous, uniform sheet through a precisely controlled process of melting, shaping, and cooling. This sheet then becomes the primary feedstock for all subsequent thermoforming operations. The quality of the final product—its dimensional accuracy, surface finish, and structural integrity—is directly dependent on the quality of the extruded sheet. A poorly extruded sheet can lead to defects, increased waste, and reduced efficiency in the forming stage.

Rayshape's expertise in this domain ensures that every sheet produced is of the highest caliber. Our extruders are designed to meet the diverse needs of manufacturers, offering compatibility with a wide range of materials such as A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, and PVC. This versatility allows our clients to produce sheets tailored for specific applications, from sustainable packaging to durable industrial components, all while prioritizing energy efficiency and automation.

Wenzhou Rayshape’s Plastic Sheet Extruder: A Closer Look at Engineering Excellence

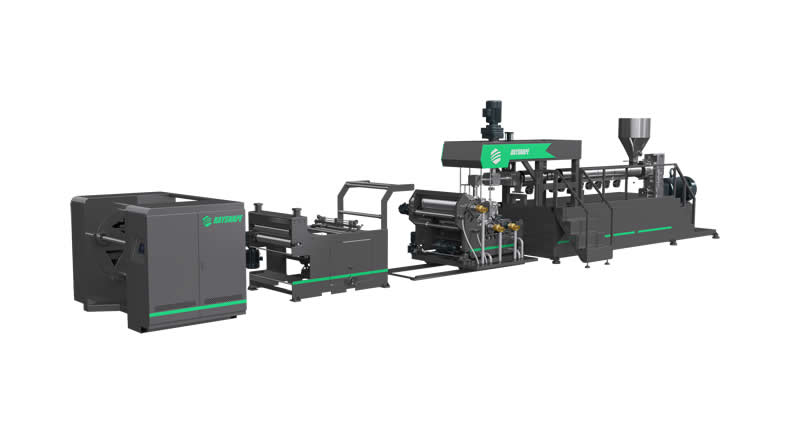

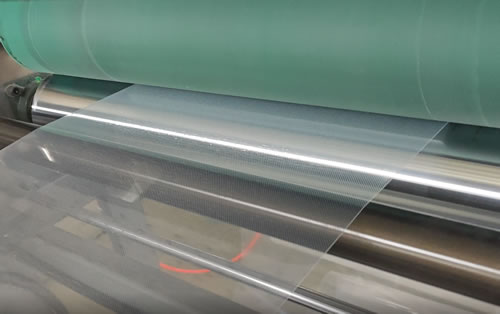

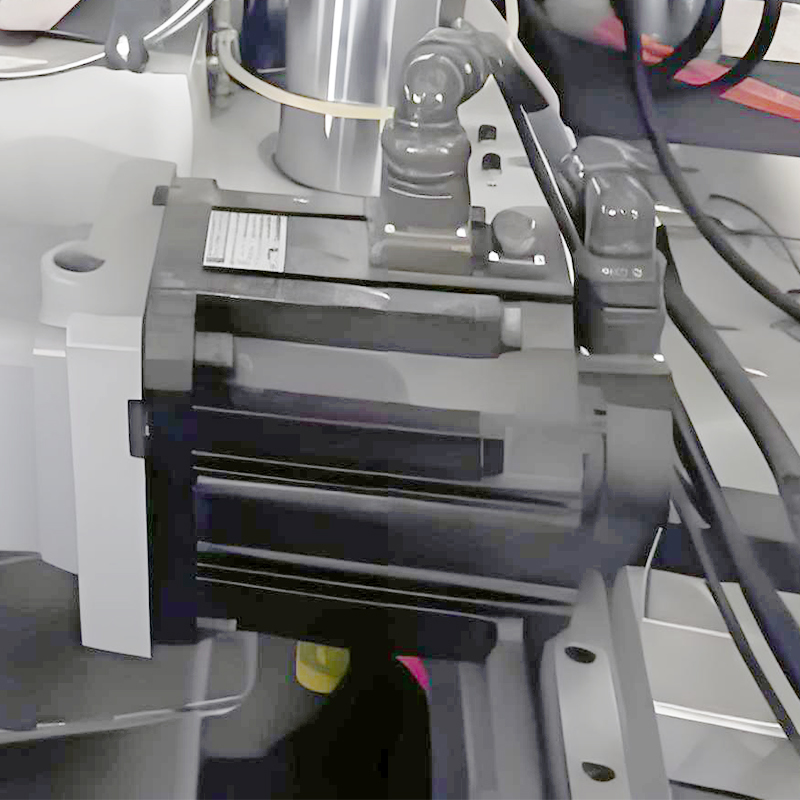

Our plastic sheet extruder models, including the RS-1000/110, RS-1000/120, and RS-1000/130, are the embodiment of our commitment to engineering perfection. These machines adopt a cast extrusion design, specifically engineered for thin sheets with high requirements for plasticization, uniform mixing, and overall sheet quality. Every component, from the screws to the motors, is sourced from well-known domestic and international brands, ensuring high efficiency and stability throughout the entire production process.

This sheet extruder adopts cast extrusion design. It is an extruder series designed for thin sheets with high plasticization requirements, uniform mixing, and high-quality sheets. It is suitable for various production requirements. All machine accessories are well-known domestic and foreign brands, ensuring high efficiency and stability throughout the production process. Applicable materials: PP, HIPS, PE and other plastic sheet extrusion, used for the production of plastic packaging products thermoforming or printing products.

| Model |

RS-1000/110 |

RS-1000/120 | RS-1000/130 |

|

Die head width |

1000mm |

1000mm |

1000mm |

|

Applicable materials |

PP.PS.PE |

PP.PS.PE |

PP.PS.PE |

|

Product width |

PP.PE:850mm PS:750mm |

PP.PE:850mm PS:750mm |

PP.PE:850mm PS:750mm |

|

Three-roller specifications |

Φ350*1000mm*1 Φ450*1000mm*2 |

Φ350*1000mm*1 Φ450*1000mm*2 |

Φ350*1000mm*1 Φ500*1000mm*2 |

|

Product thickness |

PP.PE:0.3-2mm PS:0.2-2mm |

PP.PE:0.3-2mm PS:0.2-2mm |

PP.PE:0.3-2.5mm PS:0.15-2mm |

| Screw size |

Φ110 1:32 |

Φ120 1:35 |

Φ130 1:35 |

|

Main motor power |

55kw |

132 kw |

160 kw |

|

Heating power |

40kw |

45 kw |

50 kw |

|

Total power |

100kw |

180kw |

220kw |

|

Water flow |

50m³/h |

80m³/h |

80m³/h |

|

Line speed |

15-30m/min |

15-30m/min |

15-30m/min |

|

Output |

150-200kg/h |

300-400kg/h |

400-500kg/h |

| Equipment size |

12*1.8*3m |

13*1.8*3m | 13.5*1.8*3.5m |

|

Equipment weight |

7500kg | 10500kg | 12000kg |

Specifications Of Thermoforming Machines

|

Sheet Materials |

PP/PS/PET/PLA/PE |

Air Consumption |

3m³/min |

|

Sheet Thickness |

0.2-1.5mm |

Weight |

11000kg |

|

Forming Area |

650*450mm |

Total Installed Power |

116Kw |

|

Width Of Sheet |

370-700mm |

Heating Power |

90kw |

|

Upper Forming Depth |

100mm |

Feeding Motor |

3kw |

|

Bottom Forming Depth |

130mm |

Control Forming Plug Motor Power |

3kw |

|

Max Speed |

45moulds/min |

Stacking Motor |

1.8kw |

|

The Longest Knife |

8m |

Winding Waste Of Edge Sheet Motor Power |

0.4kw |

|

Dimension |

10210*2300*2700mm |

Forming Motor |

4.4kw*2 |

|

Forming clamping force |

600kn |

Cutting Motor |

4.4kw*2 |

|

Punching clamping force |

600kn |

|

|

Advantages Of Plastic Thermoforming Machines

Loading sheet part

Load automatically, lower human resource cost.

Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Max undertake roll of sheet

Weight:600kg, Diameter 800mm.

Feeding sheet part

Automatic feeding reduces human resource costs.

Actively transport the sheet and reduce the load on the conveying servo motor.

Cleverly control the proximity switch to prevent the sheet from falling too quickly during transportation.

Human-machine interface

Controlled by microcomputer and programmable controller (PLC), all action programs can be operated through the human-machine interface, simple and convenient, 15-inch touch screen.

Heater

1. Vacuum insulation cotton is installed in the heater, which has a fast reaction speed, short processing time and energy saving.

2. The furnace body is divided into two layers, the layout of the heating tiles is optimized, so that the plate is heated evenly.

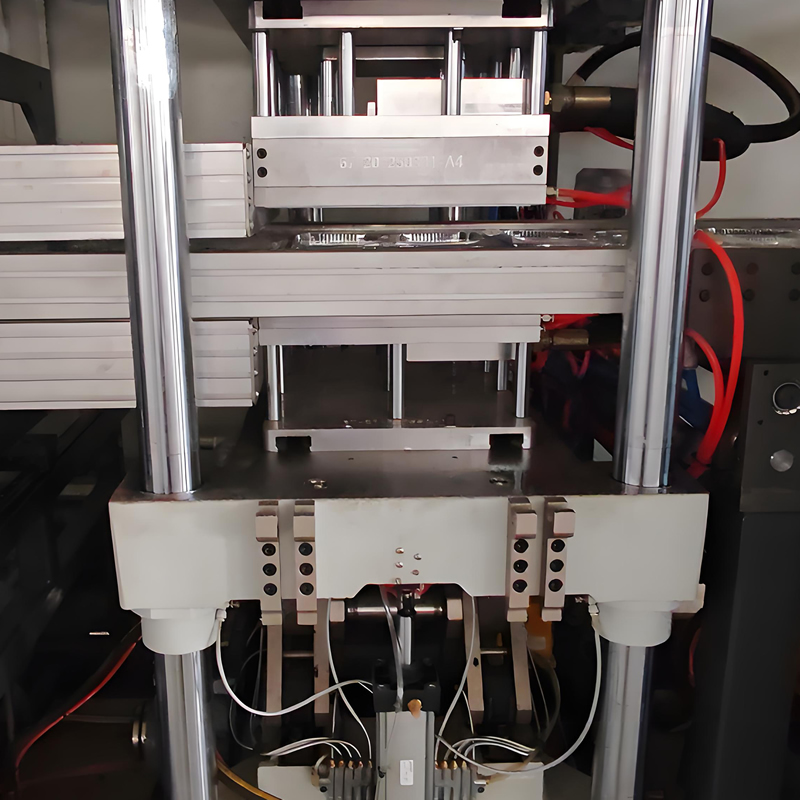

Molding station

1. Mold changing auxiliary mechanism, using sliding guide rails and support rods to achieve fast mold change, saving time and effort.

2. Adopting high-power servo motor drive, high precision, high efficiency and low noise.

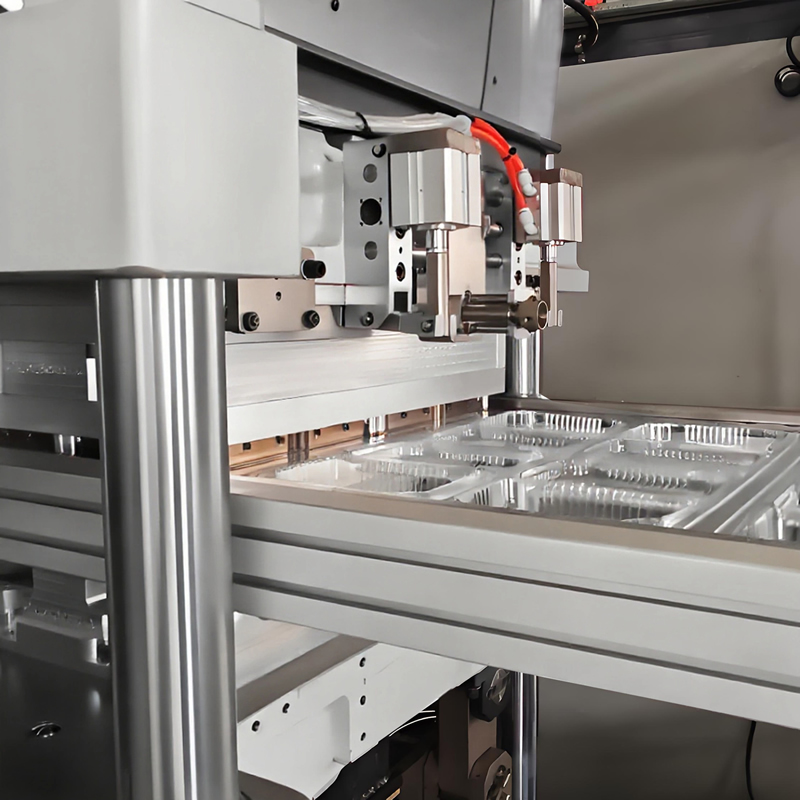

Molding mold

The working principle is a combination of positive and negative pressure, and some nylon plugs are used to assist stretching in the mold to make it have stronger molding ability.

There is cooling water in the mold cavity to speed up the cooling speed and make demolding easier.

Guide head structure

The workstation is supported by four columns (45# steel, hard chrome plated).

The integrated mold table (QT-600 steel) is made by a high-precision CNC milling machine. Therefore, it is wear-resistant, stable, and accurate, which prolongs the service life of the equipment.

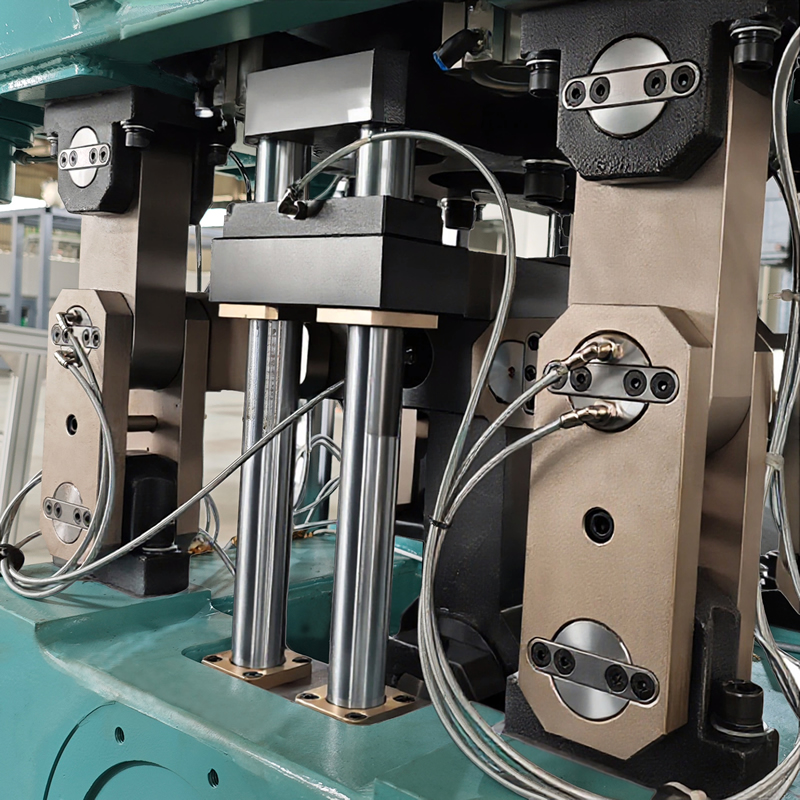

A five-point-connecting-rod structure

This structure design provides more stable operation and faster speed.

Mold change structure

The punching hole station has the same mold changing structure as the cutting station.Greatly reduce mold change time and labor costs, improve production efficiency and safety factor, and provide convenience for your diversified product chain.

Servo motor

The station mold closing, forming auxiliary stretching, and pull-tab parts are all driven by servo motors, which have fast speed, low noise, high precision, and high efficiency.

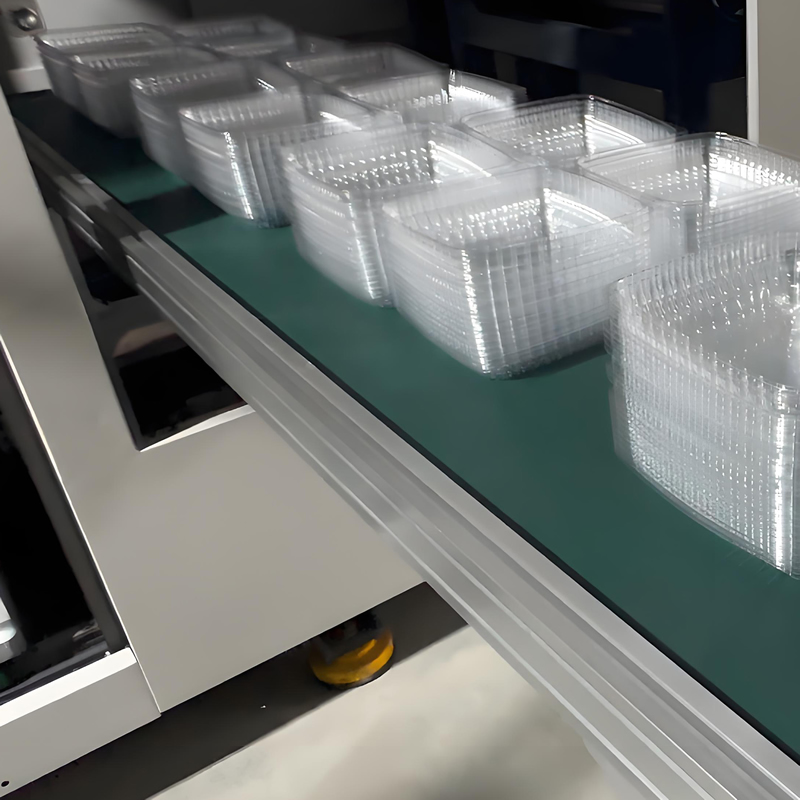

Servo-controlled conveyor belt

Set conveyor belt parameters directly on the operation screen.

Freely adjust and control conveying length and speed.

Rewinding waste of edge sheet

Our multi-station thermoformers feature a winding unit with torque motor to efficiently collect the offcuts and wind them into a roll with one side retractable, which can be conveniently removed at the end of production.

This advanced waste management system improves operating efficiency and cleanliness, making multi-station thermoformers ideal for high-quality and sustainable production.

Sheet Extruder Video

Sheet Extruder News

Rayshape Plastic sheet machine

In the dynamic world of plastic manufacturing, efficiency, precision, and sustainability are paramount. At the forefront of this industry stands Wenzhou Rayshape Machinery Co., Ltd., a leading inno...

Advanced Plastic Sheet Extrusion by Rayshape

In the fast-evolving landscape of plastic manufacturing, the foundation of every high-quality product begins with a perfectly crafted plastic sheet. From the clarity of a PET blister pack to the du...

Plastic Sheet Extruder by Wenzhou Rayshape

Introduction to Wenzhou Rayshape Machinery Co., Ltd. Wenzhou Rayshape Machinery Co., Ltd., located in Wenzhou, Zhejiang, China, is a leading manufacturer of plastic processing equipment. Spec...

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版