Thermoforming Machine

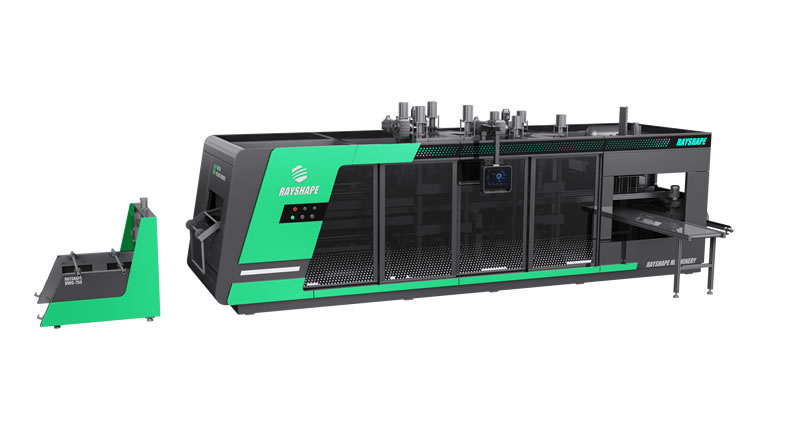

Three-Station Plastic Thermoforming Machine

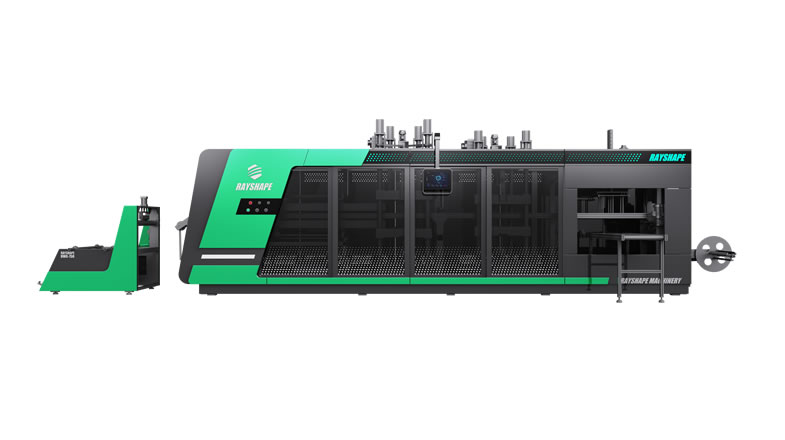

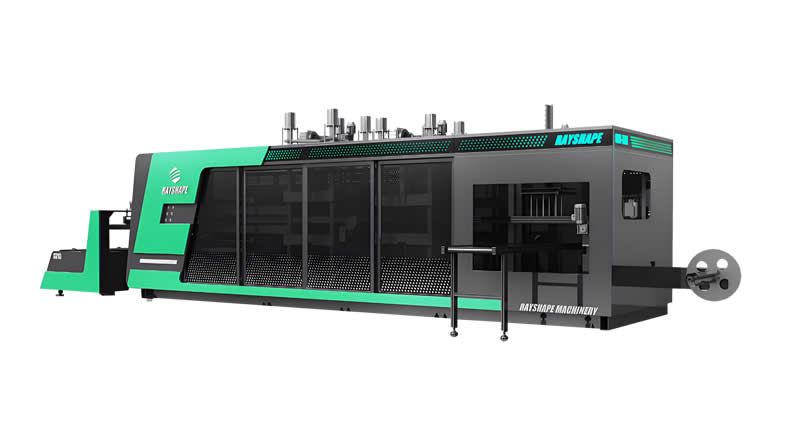

Four-Station Plastic Thermoforming Machine

Four-Station Plastic Thermoforming Machine

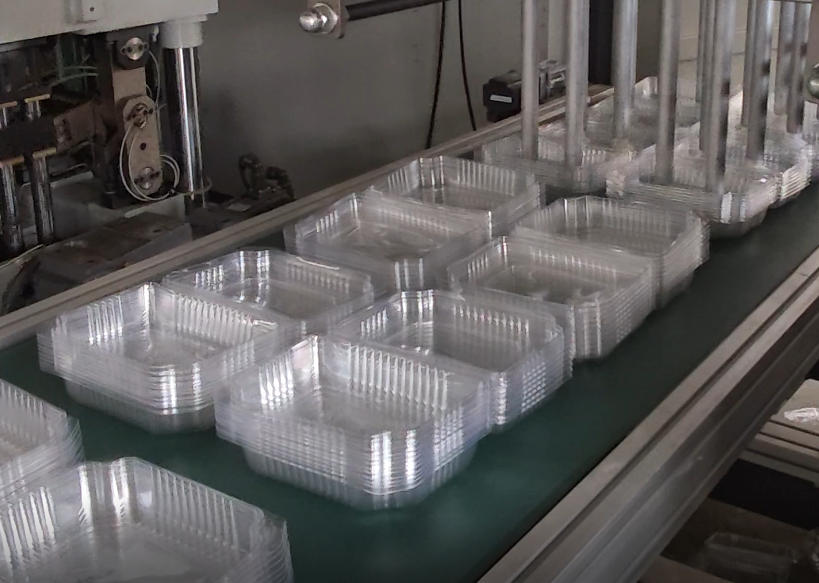

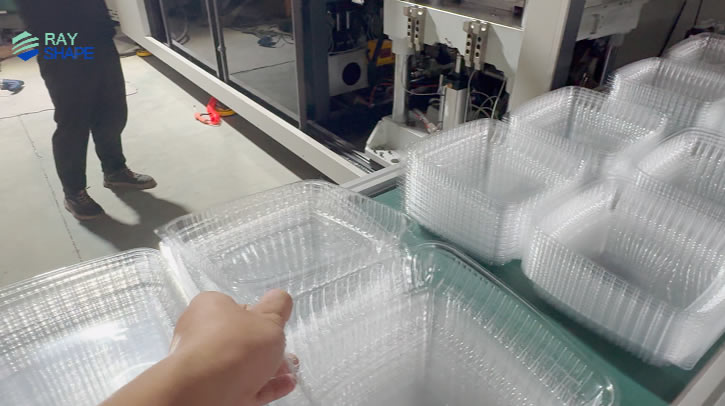

Rayshape Plastic Thermoforming Machine

Before we delve into the machines themselves, it is important to understand the thermoforming process. Thermoforming is a manufacturing process that heats a plastic sheet to a pliable temperature, forms it into a specific shape in a mold, and then trims it to create a usable product. Unlike injection molding, which involves melting the plastic and injecting it into a mold, thermoforming uses pre-extruded plastic sheets. This distinction is critical because it affects the types of products that can be manufactured, the cost of the mold, and the overall efficiency of production.

Core Principle: Heating, Forming, Trimming

The basic principle of a plastic thermoforming machine is relatively simple: controlled application of heat, followed by forming, and finally precise trimming.

Heating: The plastic sheet is heated to its softening point. This is usually achieved with radiant heaters, although other methods such as forced hot air or contact heating can also be used. The goal is to reach a temperature that makes the plastic pliable enough to be formed without degrading its properties.

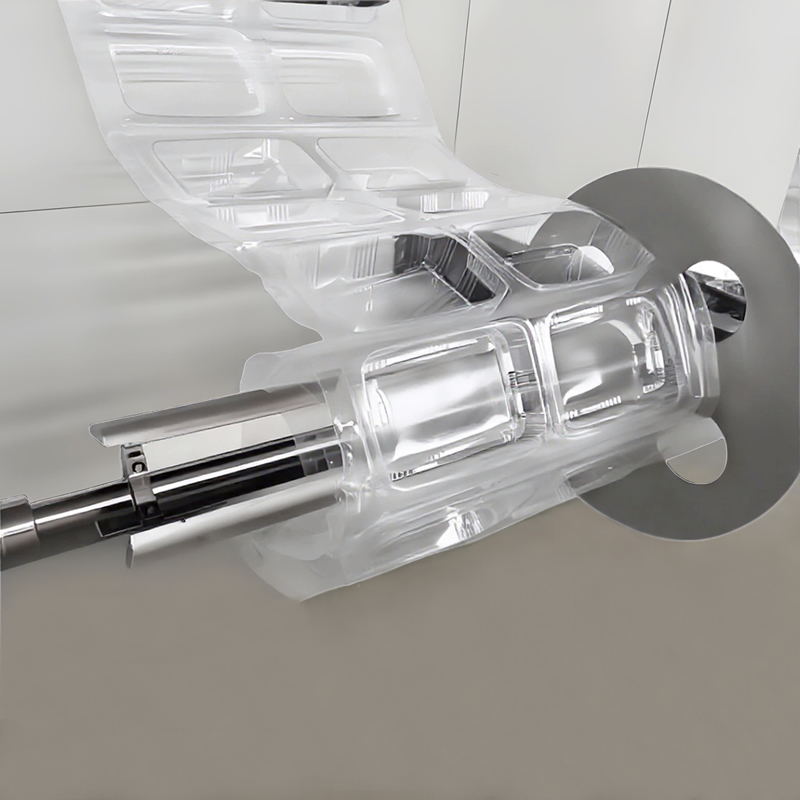

Forming: Once softened, the heated plastic sheet is brought into contact with the mold. A vacuum is then applied to draw the softened plastic tightly against the mold surface, or air pressure is used to push it into the mold cavity. This creates the desired three-dimensional shape. Some advanced machines also use plugs to pre-stretch the plastic, ensuring a more uniform wall thickness, especially for deep-draw parts.

Trimming: After the plastic has cooled and retained its shape, the formed part is removed from the mold. The excess material (often called "offcuts" or "flash") is then trimmed away to give the final product. Trimming can be performed in-line (inside the machine) or off-line, using a variety of methods such as die cutting, laser cutting, or CNC milling.

Types of Plastic Thermoforming Machines Plastic thermoforming machines come in a variety of configurations, each suited to different production volumes, part complexities, and material types. The main categories include:

1. Vacuum Forming Machines

This is the most basic and common type of thermoforming machine. They work by creating a vacuum between the heated plastic sheet and the mold, pulling the plastic into the mold cavity. Vacuum forming is suitable for parts with simpler geometries and is often used for prototyping, small batch production, and applications where dimensional accuracy is not required.

2. Positive Pressure Forming Machines

[Positive Pressure Forming Machine Image]

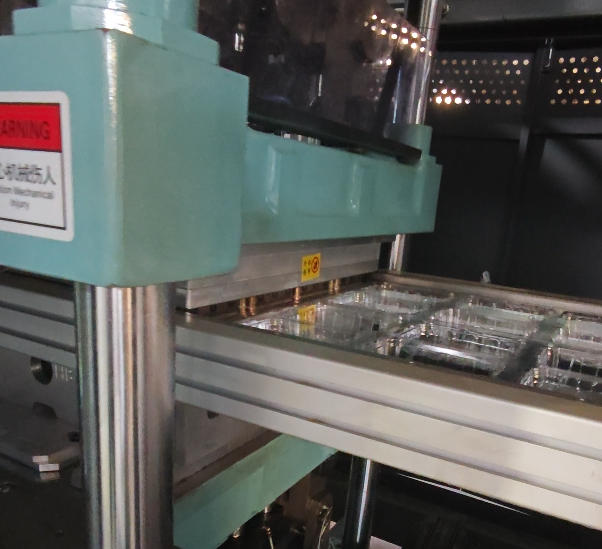

Wenzhou Ruisu Machinery Co., Ltd. specializes in the development and production of high-quality equipment, including positive and negative pressure plastic thermoforming machines. Positive pressure forming machines use air pressure to press heated plastic sheets into molds. This method has several advantages over vacuum forming, including better detail reproduction, sharper edges, and the ability to form thicker materials. Higher pressure ensures that the plastic fits the mold contours more accurately, producing parts with better aesthetics and tighter tolerances. Positive pressure forming is often used for housings, medical device components, and other applications that require a higher surface finish.

3. Twin-sheet Forming Machines

Twin-sheet thermoforming is a special process that involves heating two plastic sheets simultaneously and then forming them together in a single mold. As the sheets are formed, they fuse at the edges to form a hollow, double-walled part. This technology is ideal for producing lightweight but strong components with features inside, such as air ducts, automotive panels, and various containers.

4. Rotary Thermoformers

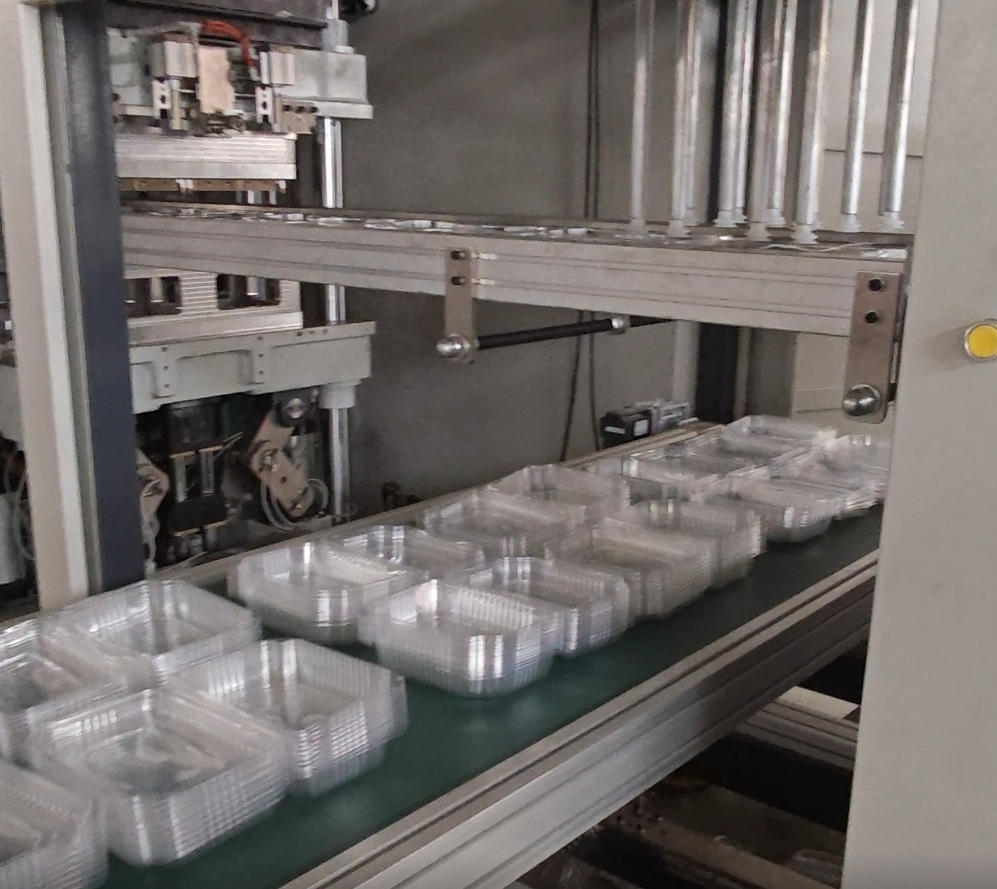

Rotary thermoformers are designed for high-volume production. They typically have multiple stations (e.g., heating, forming, cooling, trimming) arranged on a rotating indexing table. As the table rotates, each station performs its specific function, resulting in continuous and rapid production of parts. These machines are highly automated and are often used for packaging, disposable cups, and other mass-produced items.

5. In-line Thermoformers

In-line thermoformers integrate the entire process—from extruding plastic sheets to forming and trimming—into a single, continuous line. This setup is very efficient for extremely high-volume production, especially for thin-gauge products such as food packaging trays and disposable containers. The material flows directly from the extruder to the thermoforming station, minimizing handling and maximizing production output. Wenzhou Ruisu Machinery also manufactures plastic sheet extrusion lines and plastic coil forming machines, which complement the integrated concept of in-line thermoforming machines and demonstrate the company's expertise across the entire production chain.

Key Components of Thermoforming Machines

Although different types of machines vary in design, most plastic thermoforming machines share several core components:

Heating System: Usually consists of ceramic or quartz heaters arranged above and/or below the clamping frame. The heating system must provide uniform and precise temperature control to ensure consistent flexibility of the plastic.

Clamping System: The clamping system firmly holds the plastic sheet during the heating and forming process. It must apply enough force to prevent the sheet from slipping or deforming.

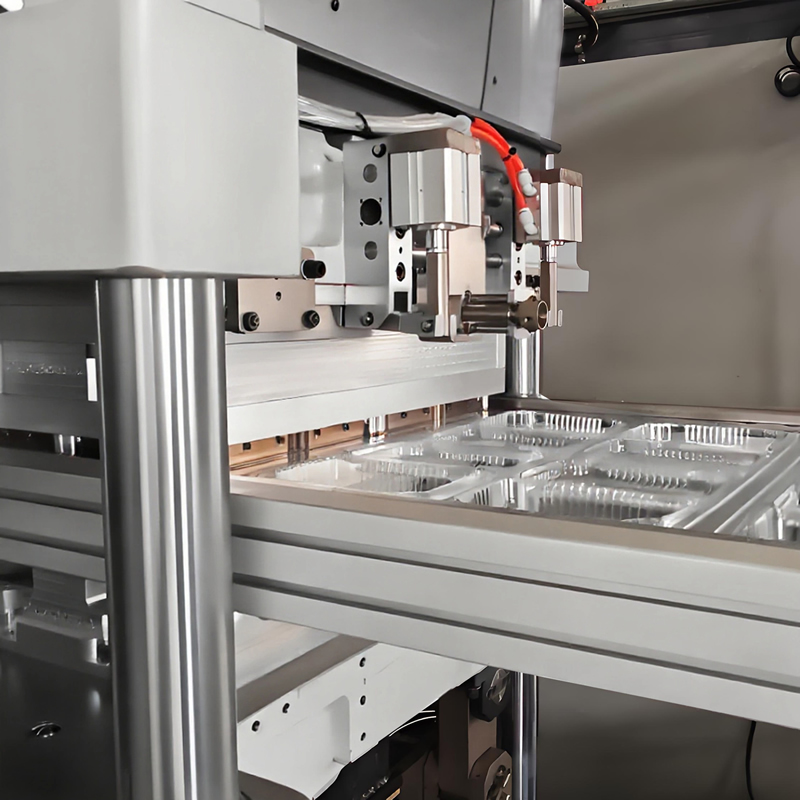

Forming Station: This is where the mold is located and where vacuum or pressure is applied to give the plastic shape.

Mold: The mold is a key component that defines the final part shape. Depending on the production volume and the material to be molded, the mold can be made of a variety of materials, including aluminum, steel, wood and even epoxy.

Vacuum/Pressure System: This includes vacuum pumps, air compressors, and control valves to regulate differential pressure during the forming process.

Cooling System: After forming, the plastic needs to be cooled quickly to fix its shape and prevent deformation. This is usually achieved by fans, water mist, or cold plates.

Finishing System: This can range from a manual trimming station to an automated die cutter, robotic trimmer, or CNC milling machine.

Control System: Modern thermoforming machines are equipped with advanced PLC (Programmable Logic Controller) or PC-based control systems. These systems allow operators to precisely control heating parameters, cycle time, pressure, and other key variables, ensuring consistent part quality and optimizing production efficiency.

Materials Used in Thermoforming

A wide variety of thermoplastics can be thermoformed, each with unique properties suitable for different applications. Common materials include:

A-PET, R-PET, C-PET (Polyethylene Terephthalate): Widely used in food packaging, beverage bottles, and blister packaging, known for its clarity, strength, and barrier properties.

BOPS (Biaxially Oriented Polystyrene): Highly transparent and rigid, it is often used in food containers and packaging.

HIPS (High Impact Polystyrene): A strong and economical material, it is often used in disposable cups, trays, and catering supplies.

PP (Polypropylene): Known for its excellent chemical resistance, heat resistance, and flexibility, it is suitable for automotive parts, containers, and medical devices.

PLA (Polylactic Acid): A biodegradable plastic that is gaining attention for sustainable packaging and disposables.

PVC (Polyvinyl Chloride): Used in blister packaging, medical trays, and other applications that require good transparency and chemical resistance.

Wenzhou Rayshape Machinery Co., Ltd. produces machines that are compatible with this wide range of materials, including A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, and PVC, allowing the production of a wide range of plastic finished products.

Applications of Plastic Thermoforming Machines

The versatility of plastic thermoforming machines has led to their widespread use in a wide range of industries. Some of the main applications include:

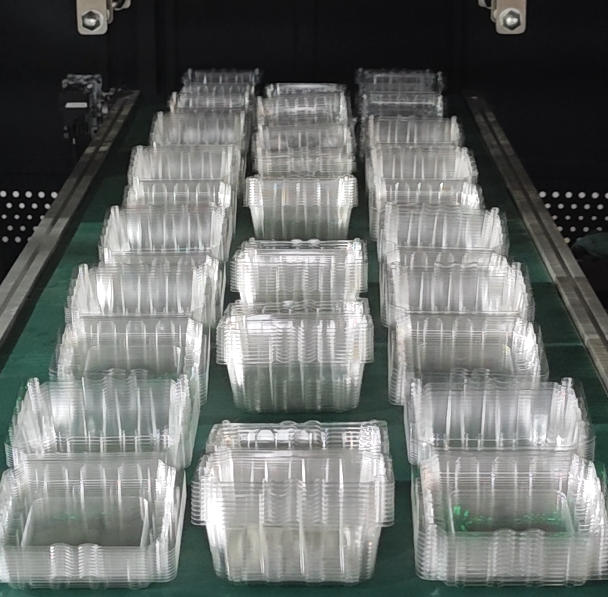

Packaging: This is probably the largest application area, covering everything from food trays, blister packs and clamshell packaging to disposable cups and containers.

Automotive: Interior trims, door panels, dashboard components, air ducts and bumper covers are often produced using thermoforming.

Medical: Medical trays, device housings, sterile packaging and prosthetic components are often produced by thermoforming because of the need for precise shapes and a sterile environment.

Consumer Products: Appliance housings, toys, sporting goods components and a variety of household items are manufactured by thermoforming.

Architectural: Skylights, bathtubs, shower enclosures and some building components can be thermoformed.

Signs and Displays: Point-of-sale displays, illuminated signage and exhibition stand components benefit from the ability to create complex shapes.

Aerospace: Interior panels, luggage and certain structural components can be thermoformed, especially for lightweight applications.

Advantages of Thermoforming

Plastic thermoforming offers several compelling advantages over other plastic manufacturing processes:

Lower tooling costs: Thermoforming tooling is generally less expensive to design and build than injection molding, making it a more cost-effective option for low- to medium-volume production.

Faster prototyping: Relatively fast and inexpensive tooling production allows for rapid prototyping and design iterations.

Design flexibility: Thermoforming can accommodate complex geometries, undercuts (with certain limitations), and textured surfaces.

Material diversity: A wide range of thermoplastic materials can be processed, providing different properties for a variety of applications.

Part size: Thermoforming can produce very large plastic parts that would be impractical or impossible with other methods.

Reduce material waste: In some thermoforming processes, particularly those with in-line trimming, scrap material can be reground and reused, contributing to sustainability.

Quick tool changeover: Modern thermoforming machines often feature quick tool changeovers, reducing downtime between different product runs.

Challenges and considerations

Despite its many advantages, thermoforming also presents some challenges and considerations:

Wall thickness variation: It is difficult to maintain uniform wall thickness, especially in deep-drawn parts or parts with sharp corners. Advanced technologies, such as plug-assisted molding and positive pressure molding, help alleviate this problem.

Limited part complexity (compared to injection molding): Although flexible, thermoforming generally cannot achieve the same level of intricate details or complex internal features as injection molding.

Material limitations: Only thermoplastics can be thermoformed; thermosets are not suitable for this process.

Waste: Although recyclable, the trimming process does generate waste that needs to be managed.

Molding limitations: Creating parts with undercuts or highly complex internal geometries can be difficult or require multi-piece molds.

Plastic Thermoforming Machine - PDF

Pursuing excellence and shaping the future

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, is located at No. 19, East Section, Pinghai Avenue, Binhai New District, Pingyang County, Wenzhou, a beautiful coastal city. This is a manufacturing enterprise integrating mechanical and software R&D, production, marketing and after-sales service.

The company was officially renamed Wenzhou Rayshape Machinery Co., Ltd. in 2025 and is wholly owned by Wenzhou Elemotion Holdings, which marks a new stage in the company's development. Wenzhou Rayshape Machinery Co., Ltd. has an experienced R&D team, strong operational and after-sales service capabilities, and a solid financial foundation. The company is committed to developing and producing high-end, energy-saving, and highly automated equipment, including positive and negative pressure plastic thermoforming machines, plastic sheet extrusion lines, and plastic coil forming machines.

The company has inherited the spirit of diligence and continuous improvement of the Elemotion Group and constantly pursues excellence in self-transcendence. Wenzhou Rayshape Machinery Co., Ltd. actively embraces innovation, has successfully developed high-quality automated equipment, and is committed to learning Elemotion's path to becoming an industry-leading company. Through unremitting efforts and commitment to technological innovation, Wenzhou Ruisu Machinery is contributing to the future of the global plastics manufacturing industry.

Specifications Of Thermoforming Machines

|

Sheet Materials |

PP/PS/PET/PLA/PE |

Air Consumption |

4m³/min |

|

Sheet Thickness |

0.2-1.5mm |

Weight |

15500kg |

|

Forming Area |

730*610mm |

Total Installed Power |

185kw |

|

Width Of Sheet |

400-800mm |

Heating Power |

140kw |

|

Upper Forming Depth |

100mm |

Feeding Motor |

4.4kw |

|

Bottom Forming Depth |

130mm |

Control Forming Plug Motor Power |

4.4kw |

|

Max Speed |

45moulds/min |

Stacking Motor |

1.8kw |

|

The Longest Knife |

10m |

Winding Waste Of Edge Sheet Motor Power |

0.4kw |

|

Dimension |

12785*2350*2700mm |

Forming Motor |

5.5kw*2 |

|

Forming clamping force |

750kn |

Cutting Motor |

5.5kw*2 |

|

Punching clamping force |

750kn |

Punching Motor |

5.5kw*2 |

Advantages Of Plastic Thermoforming Machines

Loading sheet part

Load automatically, lower human resource cost.

Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Max undertake roll of sheet

Weight:600kg, Diameter 800mm.

Feeding sheet part

Automatic feeding reduces human resource costs.

Actively transport the sheet and reduce the load on the conveying servo motor.

Cleverly control the proximity switch to prevent the sheet from falling too quickly during transportation.

Human-machine interface

Controlled by microcomputer and programmable controller (PLC), all action programs can be operated through the human-machine interface, simple and convenient, 15-inch touch screen.

Heater

1. Vacuum insulation cotton is installed in the heater, which has a fast reaction speed, short processing time and energy saving.

2. The furnace body is divided into two layers, the layout of the heating tiles is optimized, so that the plate is heated evenly.

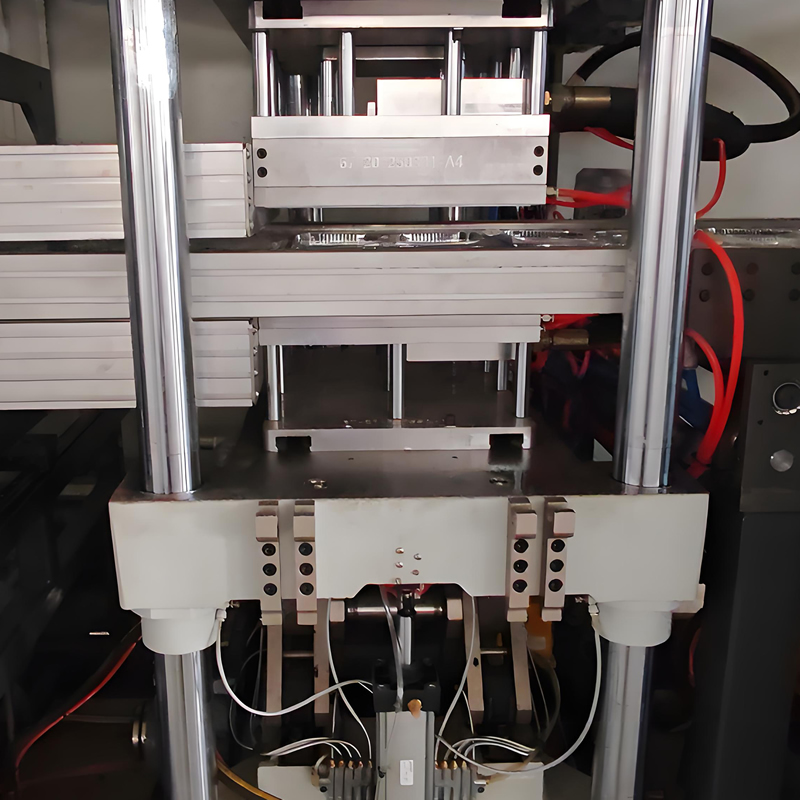

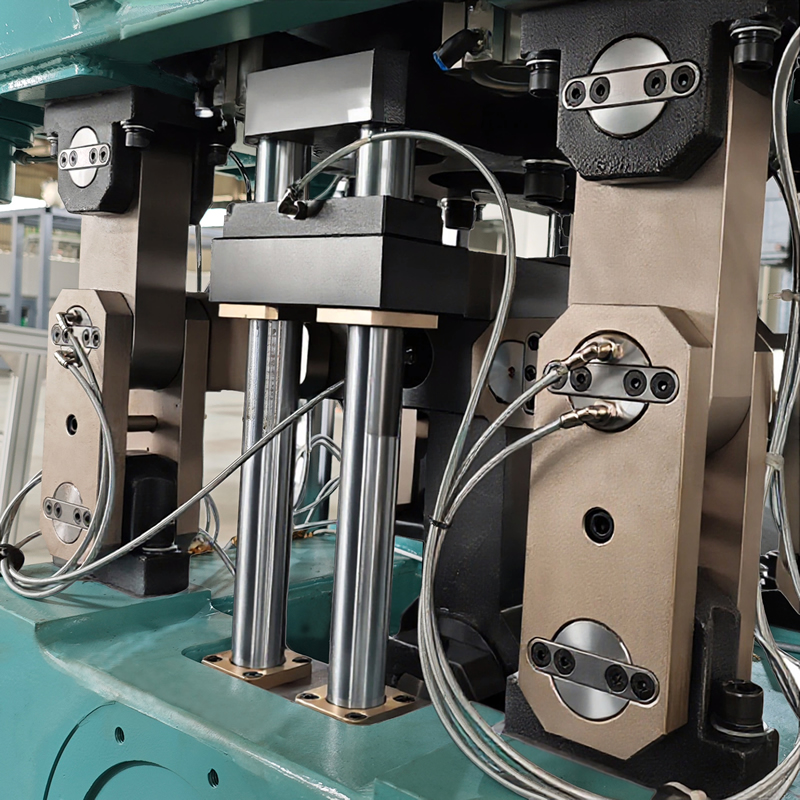

Molding station

1. Mold changing auxiliary mechanism, using sliding guide rails and support rods to achieve fast mold change, saving time and effort.

2. Adopting high-power servo motor drive, high precision, high efficiency and low noise.

Molding mold

The working principle is a combination of positive and negative pressure, and some nylon plugs are used to assist stretching in the mold to make it have stronger molding ability.

There is cooling water in the mold cavity to speed up the cooling speed and make demolding easier.

Guide head structure

The workstation is supported by four columns (45# steel, hard chrome plated).

The integrated mold table (QT-600 steel) is made by a high-precision CNC milling machine. Therefore, it is wear-resistant, stable, and accurate, which prolongs the service life of the equipment.

A five-point-connecting-rod structure

This structure design provides more stable operation and faster speed.

Mold change structure

The punching hole station has the same mold changing structure as the cutting station.Greatly reduce mold change time and labor costs, improve production efficiency and safety factor, and provide convenience for your diversified product chain.

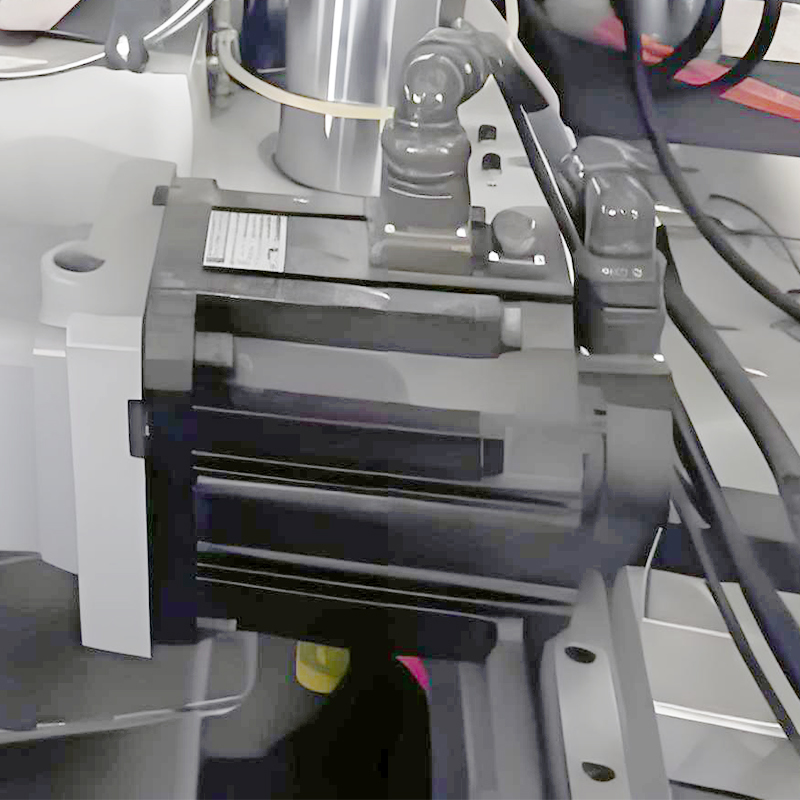

Servo motor

The station mold closing, forming auxiliary stretching, and pull-tab parts are all driven by servo motors, which have fast speed, low noise, high precision, and high efficiency.

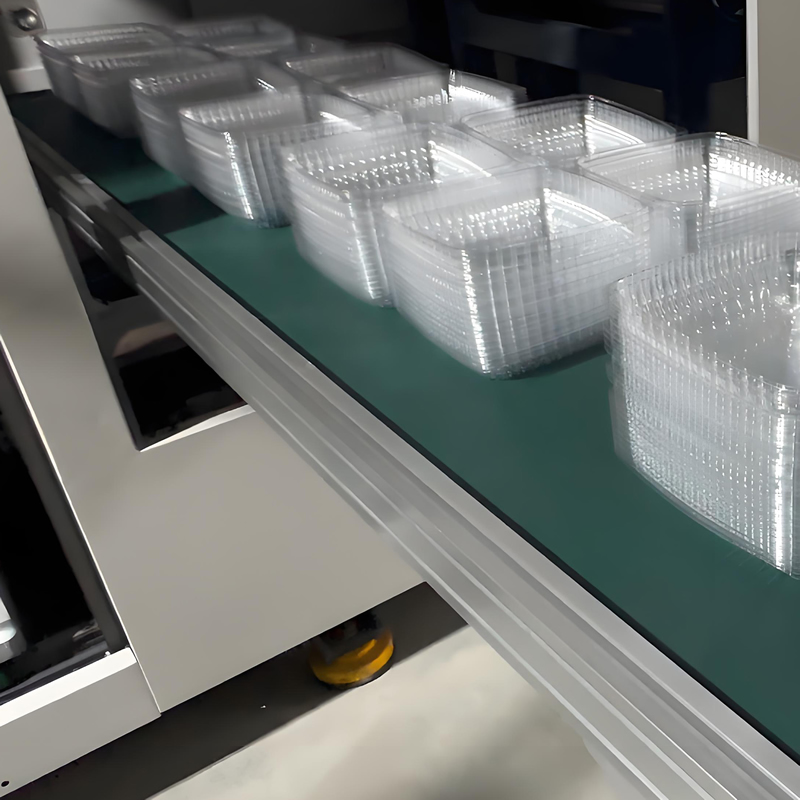

Servo-controlled conveyor belt

Set conveyor belt parameters directly on the operation screen.

Freely adjust and control conveying length and speed.

Rewinding waste of edge sheet

Our multi-station thermoformers feature a winding unit with torque motor to efficiently collect the offcuts and wind them into a roll with one side retractable, which can be conveniently removed at the end of production.

This advanced waste management system improves operating efficiency and cleanliness, making multi-station thermoformers ideal for high-quality and sustainable production.

Thermoforming Machine Video

Thermoforming Machine News

Leading Plastic Thermoforming Machine Enterprise in Binhai New Area

Wenzhou Rayshape Machinery Co., Ltd., located in the Binhai New Area of Wenzhou, is a leading enterprise in the production of the Plastic Thermoforming Machine. As a key subsidiary of the Elemotion...

High Volume Food Box Machine for Professional Catering

The professional catering industry requires the high-volume output of the Food Box Machine from Wenzhou Rayshape Machinery Co., Ltd. As part of the Elemotion Group, we are based in Wenzhou and spec...

Automatic Plastic Box Making Machine for Global Supply Chains

Global supply chains demand the efficiency of the Automatic Plastic Box Making Machine from Wenzhou Rayshape Machinery Co., Ltd. A subsidiary of Elemotion Group, we are located at No. 19, East Sect...

BOPS and HIPS Compatible Plastic Container Making Machine

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, offers a Plastic Container Making Machine that is fully compatible with BOPS and HIPS. Located in the coastal Binhai New Area ...

PP Plastic Thermoforming Machine Stability for Microwaveable Trays

Microwaveable trays require the stability of the PP Plastic Thermoforming Machine from Wenzhou Rayshape Machinery Co., Ltd. As part of Elemotion Group, our company in Wenzhou focuses on high-end au...

Advanced Plastic lid forming machine for High Clarity PET

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, provides an Advanced Plastic lid forming machine for high-clarity PET packaging. Located at No. 19, East Section of Pinghai Av...

Multi Station Plastic Thermoforming Equipment for Reliable Output

Reliability is the hallmark of the Multi Station Plastic Thermoforming Equipment from Wenzhou Rayshape Machinery Co., Ltd. A member of the Elemotion Group, our company is based in Pingyang County, ...

Plastic Box Forming Machine for Retail and Electronic Protection

Retail and electronic protection require high-quality packaging, and the Plastic Box Forming Machine from Wenzhou Rayshape Machinery Co., Ltd. is the perfect solution. As a subsidiary of Elemotion ...

Fully Automatic Thermoforming Machine Innovation by Rayshape

Wenzhou Rayshape Machinery Co., Ltd., a key subsidiary of the Elemotion Group, is leading the industry with the Fully Automatic Thermoforming Machine. Based at No. 19, East Section of Pinghai Avenu...

Bowl Making Machine Performance and Reliable Production Output

Wenzhou Rayshape Machinery Co., Ltd., a member of the Elemotion Group, offers a high-performance Bowl Making Machine designed for the food service industry. Located in the Binhai New Area of Wenzho...

Precision Cup Making Machine for Fast Food Beverage Industry

The fast food beverage industry demands high-speed precision, and the Cup Making Machine from Wenzhou Rayshape Machinery Co., Ltd. delivers exactly that. As a subsidiary of Elemotion Group in Wenzh...

Energy Efficient Plastic Thermoforming Equipment for Eco Friendly Trays

Wenzhou Rayshape Machinery Co., Ltd., part of the Elemotion Group, is committed to green manufacturing with our Energy Efficient Plastic Thermoforming Equipment. Based in Wenzhou, we specialize in ...

Versatile Plastic Forming Machine for PVC and HIPS Materials

The Versatile Plastic forming machine from Wenzhou Rayshape Machinery Co., Ltd. is designed to handle the diverse material requirements of modern packaging. As a subsidiary of Elemotion Group, we a...

High Performance Plastic Box Making Machine with Software Control

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, offers a High Performance Plastic Box Making Machine featuring advanced software control. Located at No. 19, East Section of P...

Plastic Container Machine Efficiency for Polypropylene Packaging

Polypropylene (PP) packaging is essential for heat-resistant food containers, and the Plastic Container Machine from Wenzhou Rayshape Machinery Co., Ltd. is optimized for this material. A proud sub...

Durable Vacuum Forming Machine for Industrial Plastic Applications

Industrial plastic applications require the durability and precision of the Vacuum Forming Machine from Wenzhou Rayshape Machinery Co., Ltd. As a subsidiary of Elemotion Group, we are located in th...

Fruit Box Making Machine for Global Agricultural Logistics

The global agricultural logistics sector relies on high-quality packaging, and the Fruit box making machine from Wenzhou Rayshape Machinery Co., Ltd. is the industry standard. As a subsidiary of El...

Plastic Sheet Extruder Integration with Thermoforming Equipment

For a complete production solution, Wenzhou Rayshape Machinery Co., Ltd. offers the Plastic Sheet Extruder designed to work seamlessly with our thermoforming equipment. Based in Wenzhou and part of...

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版