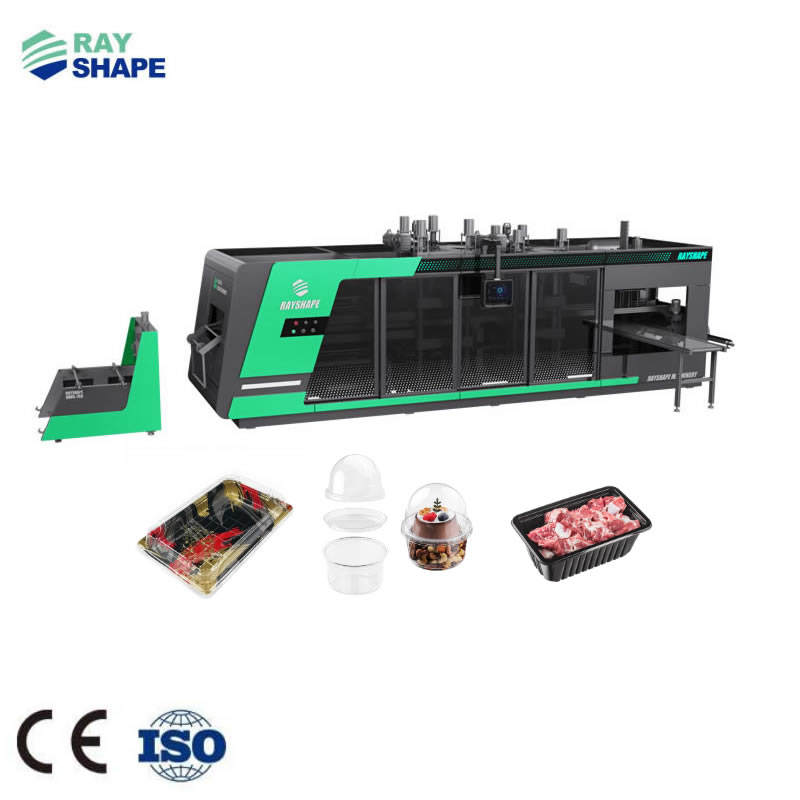

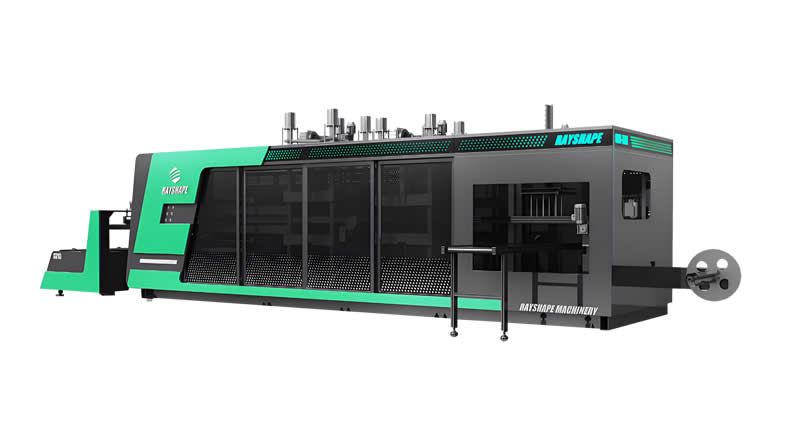

Custom mold Plastic Thermoforming Machine for PET trays

Model: RS-650-450-3

As a highly advanced iteration of the Plastic Thermoforming Machine, the PET Thermoforming Machine is specifically engineered to address the un...

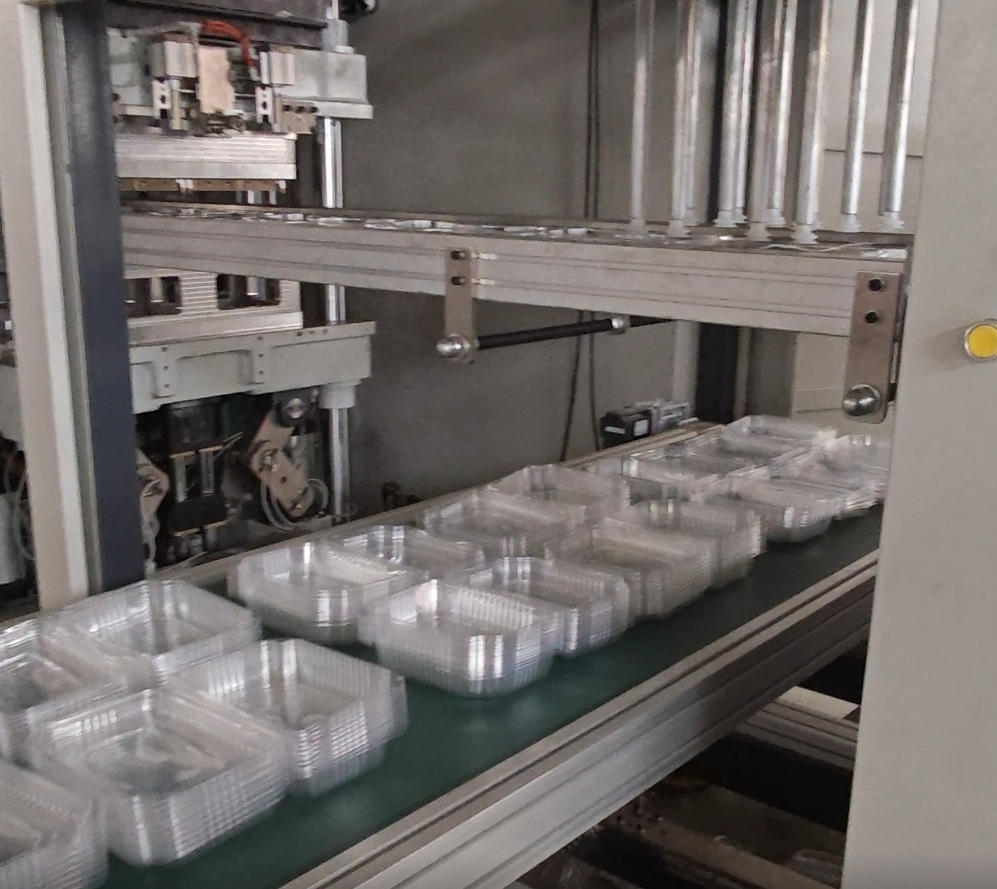

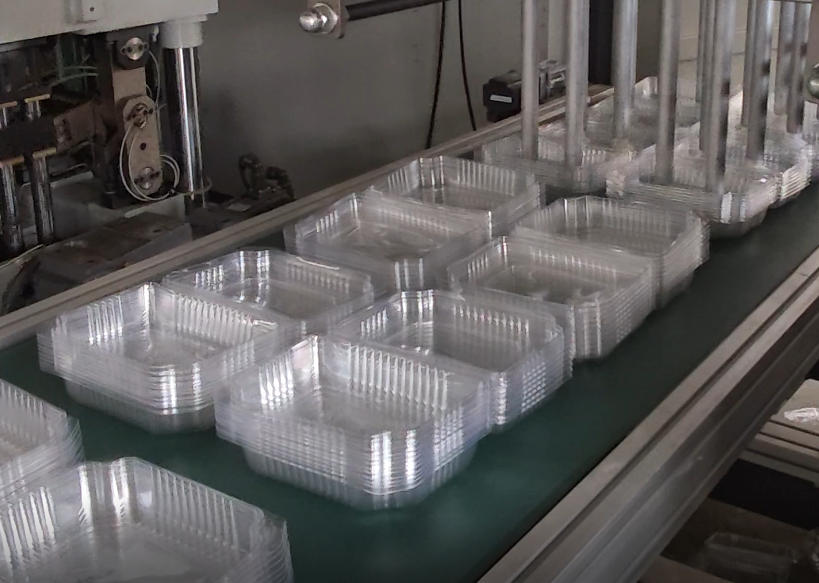

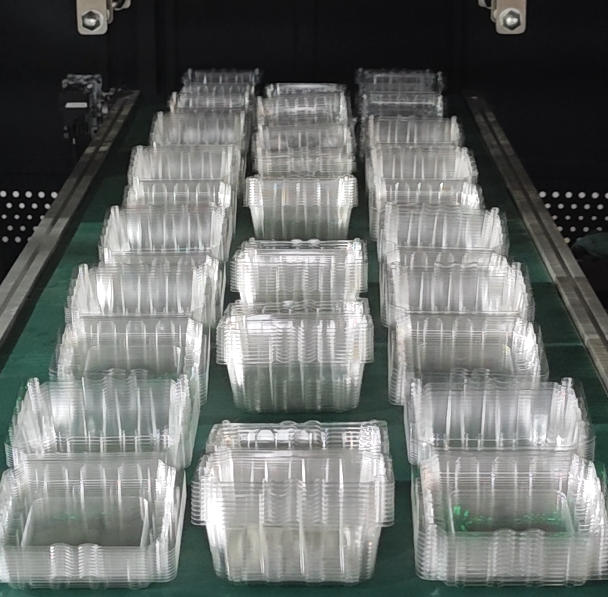

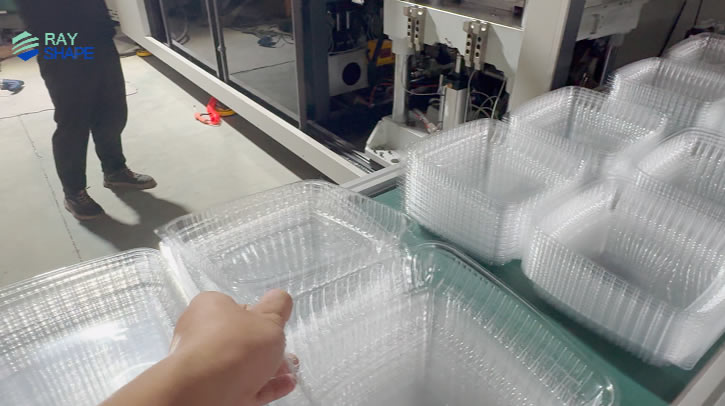

thermoforming machine are suitable for processing different materials such as A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, PVC and barrier materials, and can produce a variety of products: trays, lids, fruit and vegetable boxes, flower pots, shells, seedling trays and plates.

It can make some products that single-station thermoforming machines cannot make, such as: PLA products, plastic lids or containers with holes, packaging containers with connected bodies and lids (fruit boxes, egg trays), etc.

1. High degree of standardization, complete functions, safe, efficient, energy-saving and hygienic.

2. It integrates mechanical, pneumatic and electrical integration, and is controlled by microcomputer and programmable controller (PLC).

3. Easy-to-operate human-machine interface, and has the function of remote connection.

4. Electric lifting, double-station large-diameter unwinding, allowing a single person to load coils weighing up to 600KG.

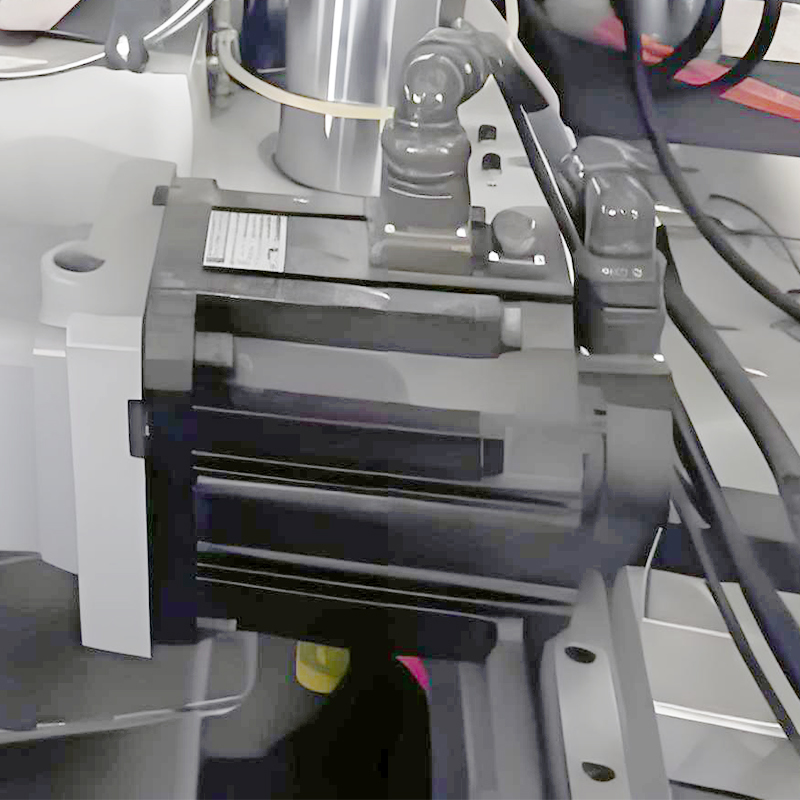

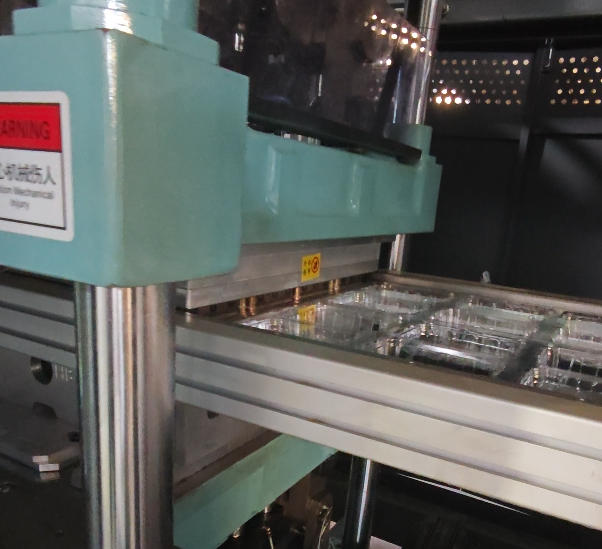

5. Servo feeding, stepless adjustment of sheet length, high speed, accuracy and stability.

6. The upper and lower electric heating furnaces are used for four-stage heating and protection to reduce the impact of air convection on temperature, so that the product molding is stable, from 0-400 degrees in just 3 minutes, improving production efficiency. The electric heating furnace can automatically remove the device.

7. A new real-time distributed digital dynamic hot forming temperature control system is used to control the temperature of the tile at a single point, and it has automatic compensation control, with an accuracy of ±1℃. Energy saving of about 15% and extended furnace plate service life.

8. The quick mold change system can conveniently, quickly, accurately and safely change molds, reduce machine downtime, reduce labor waste, and improve production efficiency.

9. The mold opening and closing of the forming, punching and cutting stations are controlled by servo motors, with high precision, low wear, fast speed and low noise. Each station is supported by four columns, combined with a five-point structural connecting rod, which has good stability.

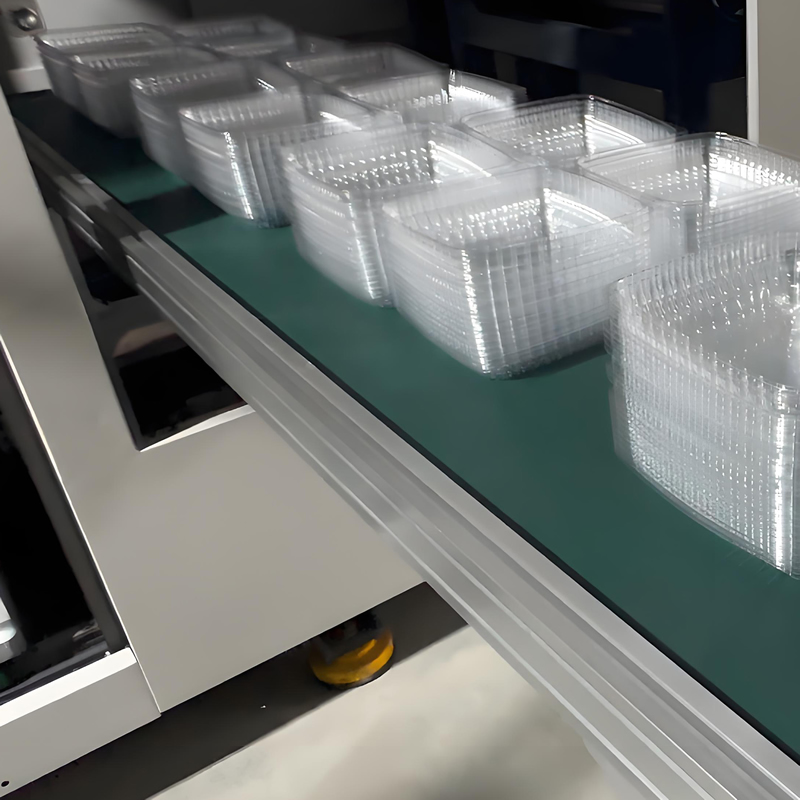

10. The unique vertical stacking concept ensures continuous stacking of products.

11. Automatic counting of finished product output, with production data memory function, can store 90 sets of operating data.

12. Combined with the edge material winding device, the entire production process is clean, without burrs and waste.

13. The design of the electrical cabinet is simple and refreshing, simplifying the machine assembly and wiring installation process.

| Model |

450/650 |

730/610 | 730/810 | |

|

Sheet thickness |

0.2-1.5mm |

0.2-1.5mm |

0.2-1.5mm | |

|

Applicable materials |

PP PET PVC PS PLA |

PP PET PVC PS PLA |

PP PET PVC PS PLA | |

|

Maximum molding area |

450x630mm |

730x610mm | 730X810 | |

|

Sheet width |

350-700mm |

400-800mm |

400-800mm | |

|

Maximum forming depth of upper die |

100mm |

100mm |

100mm | |

|

Maximum forming depth of lower die |

130mm |

130mm |

130mm | |

|

Maximum speed |

40/min |

40/min |

40/min | |

|

Heating power |

78KW |

125KW |

156KW | |

|

Main motor power |

4.4kw x 4 4.4kw x 6 |

5.5kw x 4 5.5kw x 6 |

7.5kw x 4 7.5kw x 6 |

|

|

Feeding motor power |

3kw |

4.4kw | 4.4kw | |

|

Stretching motor power |

3kw | 4.4kw | 4.4KW | |

|

Stacking power |

2.3kw | 2.3kw | 2.3kw | |

|

Winding motor power |

0.55kw |

0.55kw |

0.55kw | |

|

Air consumption |

2.5m²/min 0.5-0.8 bar |

3.5m²/min 0.5-0.8 bar |

4m²/min 0.5-0.8 bar |

|

|

Total power |

115kw |

160kw | 198KW | |

|

Weight |

8.5T | 13T | 15T | |

|

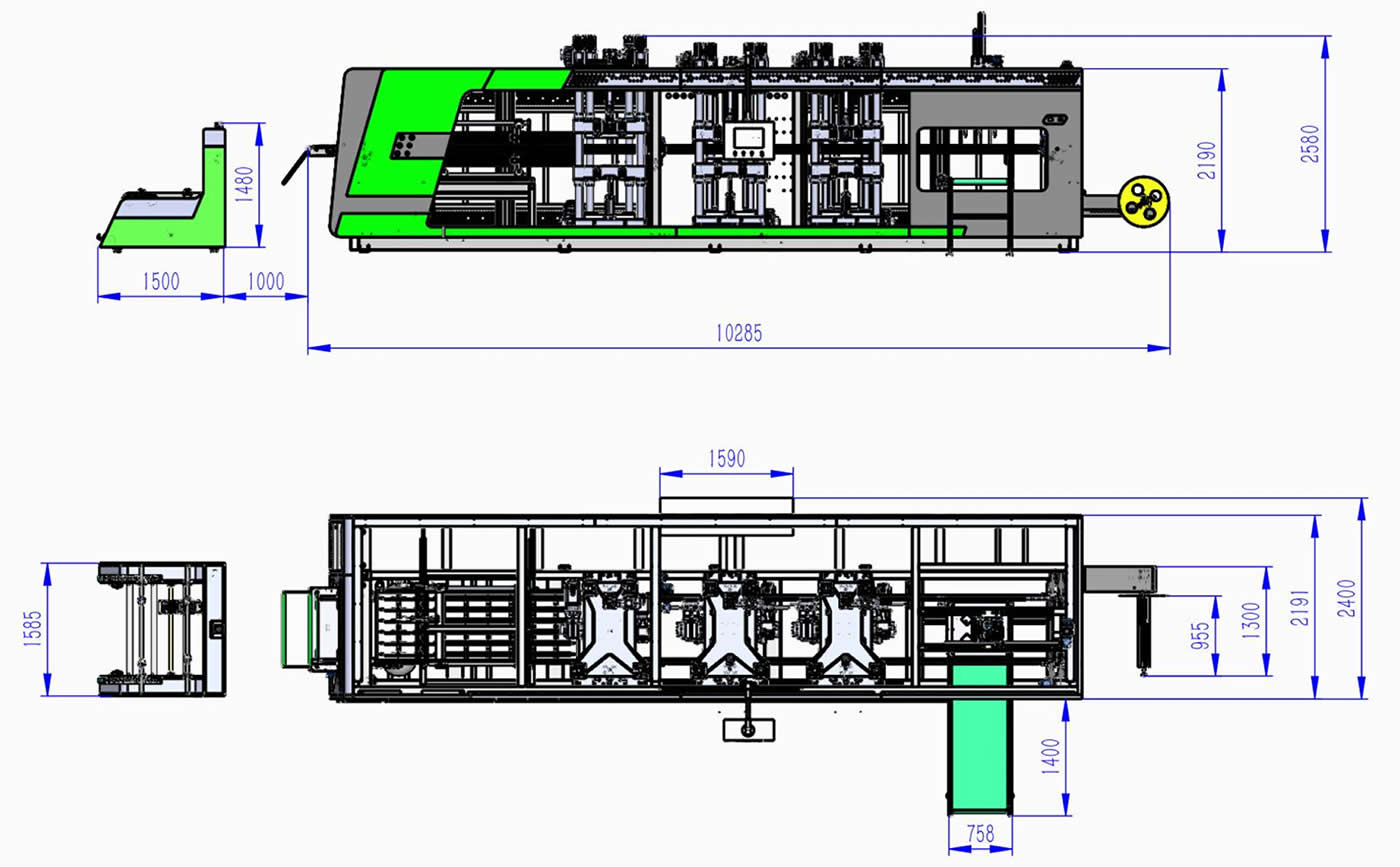

Overall machine size |

8x2.25x2.7m | 11mx2.35mx2.7 | 13.5mx2.35x2.7m |

Load automatically, lower human resource cost.

Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Max undertake roll of sheet

Weight:600kg, Diameter 800mm.

Automatic feeding reduces human resource costs.

Actively transport the sheet and reduce the load on the conveying servo motor.

Cleverly control the proximity switch to prevent the sheet from falling too quickly during transportation.

Controlled by microcomputer and programmable controller (PLC), all action programs can be operated through the human-machine interface, simple and convenient, 15-inch touch screen.

1. Vacuum insulation cotton is installed in the heater, which has a fast reaction speed, short processing time and energy saving.

2. The furnace body is divided into two layers, the layout of the heating tiles is optimized, so that the plate is heated evenly.

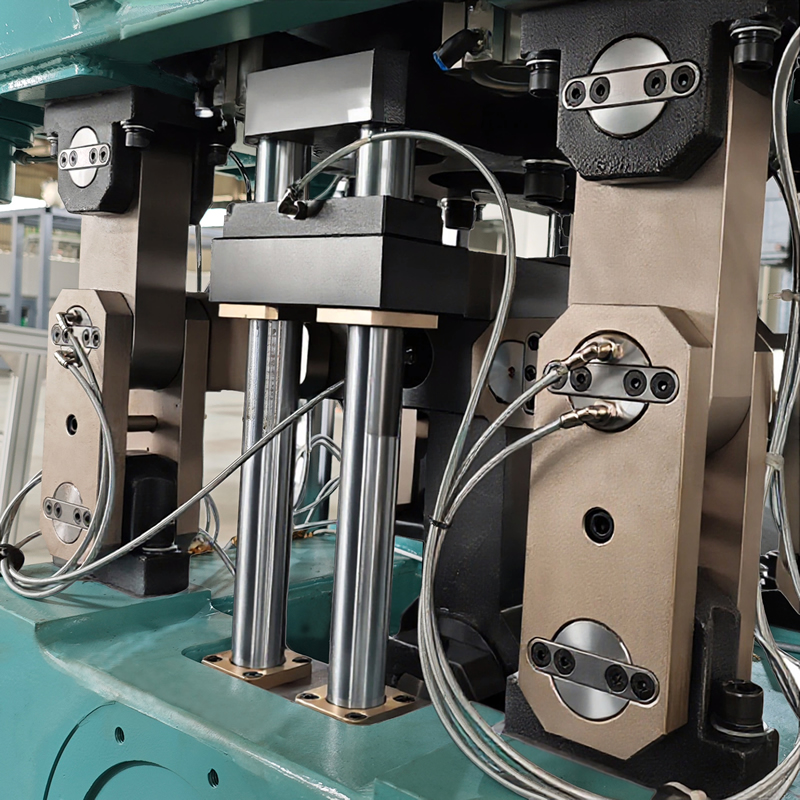

1. Mold changing auxiliary mechanism, using sliding guide rails and support rods to achieve fast mold change, saving time and effort.

2. Adopting high-power servo motor drive, high precision, high efficiency and low noise.

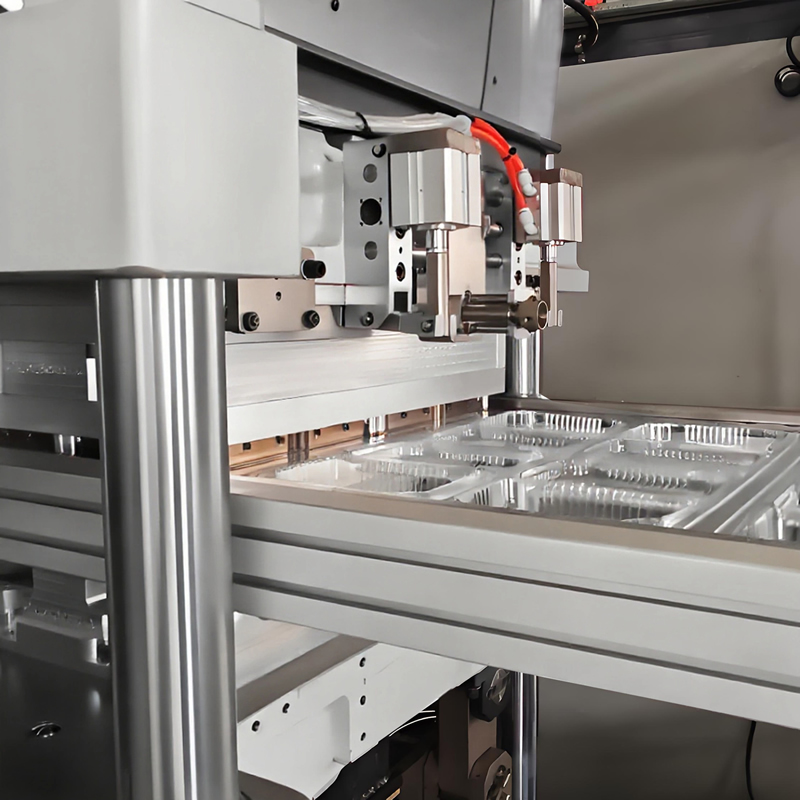

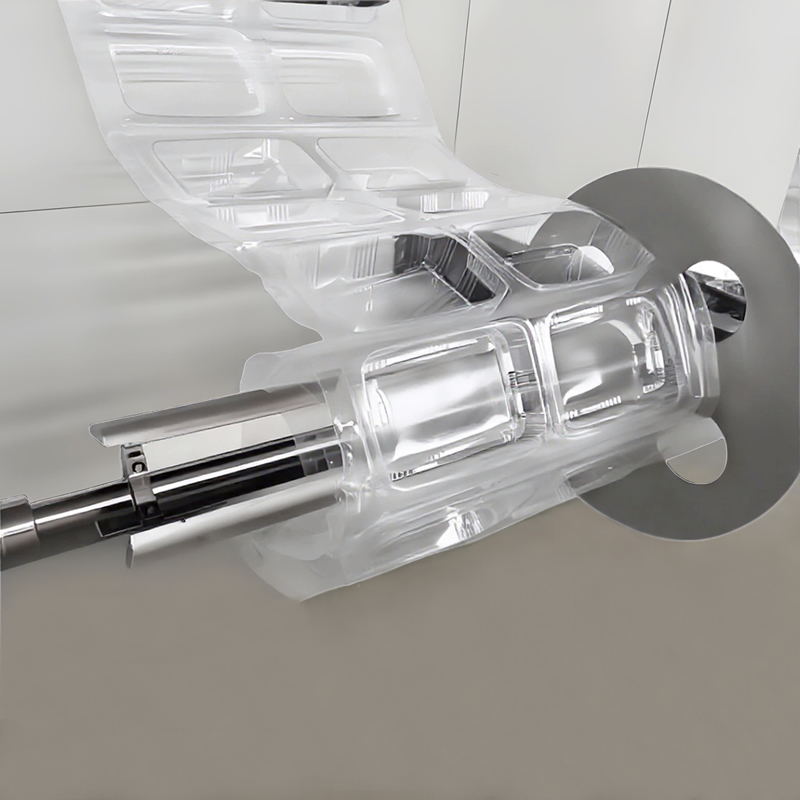

The working principle is a combination of positive and negative pressure, and some nylon plugs are used to assist stretching in the mold to make it have stronger molding ability.

There is cooling water in the mold cavity to speed up the cooling speed and make demolding easier.

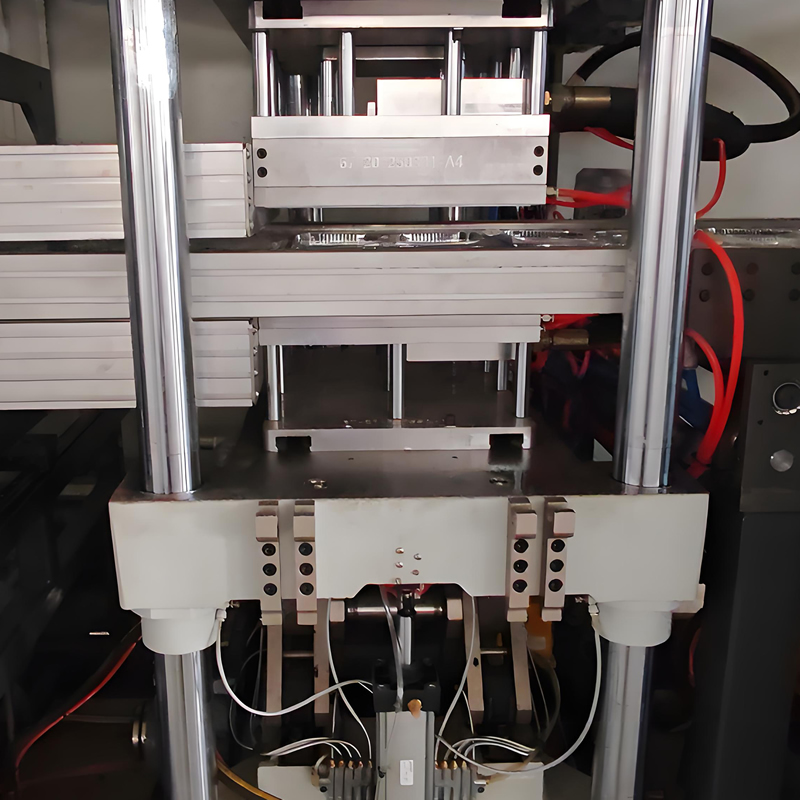

The workstation is supported by four columns (45# steel, hard chrome plated).

The integrated mold table (QT-600 steel) is made by a high-precision CNC milling machine. Therefore, it is wear-resistant, stable, and accurate, which prolongs the service life of the equipment.

This structure design provides more stable operation and faster speed.

The punching hole station has the same mold changing structure as the cutting station.Greatly reduce mold change time and labor costs, improve production efficiency and safety factor, and provide convenience for your diversified product chain.

The station mold closing, forming auxiliary stretching, and pull-tab parts are all driven by servo motors, which have fast speed, low noise, high precision, and high efficiency.

Set conveyor belt parameters directly on the operation screen.

Freely adjust and control conveying length and speed.

Our multi-station thermoformers feature a winding unit with torque motor to efficiently collect the offcuts and wind them into a roll with one side retractable, which can be conveniently removed at the end of production.

This advanced waste management system improves operating efficiency and cleanliness, making multi-station thermoformers ideal for high-quality and sustainable production.

Please fill in the following information

Model: RS-650-450-3

As a highly advanced iteration of the Plastic Thermoforming Machine, the PET Thermoforming Machine is specifically engineered to address the un...

Model: RS-650-450-3

PET Automated Production Solutions: Derived from advanced Plastic Thermoforming Machine technology, the PET Thermoforming Machine is a reliable, hi...

Model: RS-650-450-4

RS-650-450-4 Pet Thermoforming Machine, uses internationally advanced plastic sheet forming technology. It is a plastic sheet forming equi...

Model: RS-650-450-4

The PET Thermoforming Machine represents a significant advancement in specialized manufacturing, leveraging the core technology of the Pla...

Wenzhou Rayshape Machinery Co., Ltd., a member of the Elemotion Group, offers a high-performance Bowl Making Machine designed for the food service industry. Located in the Binhai New Area of Wenzho...

Automatic multi-station thermoforming machines revolutionize plastic manufacturing by combining heating, forming, cutting, and stacking in a seamless, automated process. These machines exc...

Industrial plastic applications require the durability and precision of the Vacuum Forming Machine from Wenzhou Rayshape Machinery Co., Ltd. As a subsidiary of Elemotion Group, we are located in th...

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, is located in the coastal city of Pingyang County, Wenzhou. Our High Capacity Plastic Container Making Machine is engineered to s...

The Ultimate in Efficiency: Rayshape's Three-Station Thermoforming Machine for Fruit Trays In the highly competitive food packaging industry, speed, hygiene, and precision are non-negotiable. For m...

A blister forming machine excels in producing airtight packaging for tablets, capsules, or small consumer items. It works by heating a plastic sheet, forming it into cavities (blisters) using vacuum s...

Industrial storage requires durability, and the Reliable Plastic Box Making Machine from Wenzhou Rayshape Machinery Co., Ltd. provides exactly that. As a subsidiary of Elemotion Group, we are a leadin...

Wenzhou Rayshape Machinery Co., Ltd. provides a Versatile Plastic box forming machine that serves both the retail and catering sectors. As a subsidiary of Elemotion Group, we are located in the coasta...

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, offers a High Performance Plastic Box Making Machine featuring advanced software control. Located at No. 19, East Section of P...

Wenzhou Rayshape Machinery Co., Ltd. is championing eco-friendly packaging with our Sustainable PET Thermoforming Machine. As a key subsidiary of Elemotion Group, we are a manufacturing enterprise tha...

Microwaveable trays require the stability of the PP Plastic Thermoforming Machine from Wenzhou Rayshape Machinery Co., Ltd. As part of Elemotion Group, our company in Wenzhou focuses on high-end au...

The future of manufacturing is smart, and Wenzhou Rayshape Machinery Co., Ltd. is leading the way with our future-oriented control systems for the Plastic Thermoforming Machine. As a part of Elemot...

Agricultural products like nursery plates and seedling trays require specific material stretching capabilities. Wenzhou Rayshape Machinery Co., Ltd., an Elemotion Group company, offers a Plastic Th...

Producing flanged or round products like flower pots and soup bowls requires precision that standard machines cannot always provide. Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion ...

Industrial packaging requires precision and durability, and Wenzhou Rayshape Machinery Co., Ltd. provides both with our Professional Plastic Box Making Machine. As a subsidiary of Elemotion Group, we ...

The China thermoforming machine industry has transformed from a provider of cost-effective solutions to a global leader in innovation and quality. Chinese manufacturers, like Wenzhou Rayshape Machi...