Thermoforming Machine

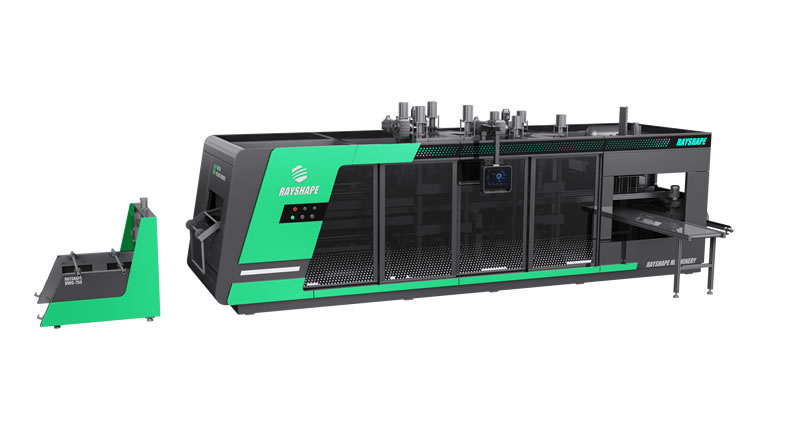

Three-Station Plastic Thermoforming Machine

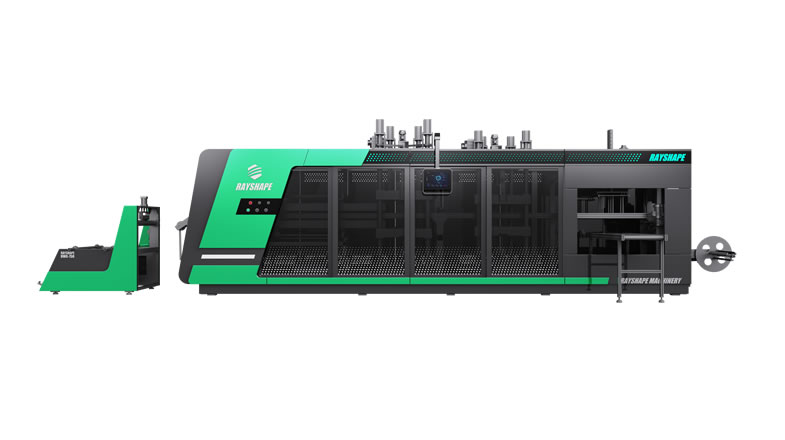

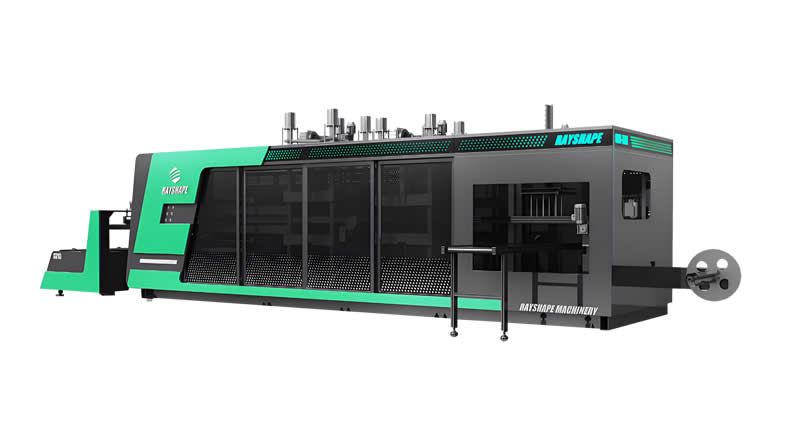

Four-Station Plastic Thermoforming Machine

Four-Station Plastic Thermoforming Machine

Understanding the Basics of a Thermoforming Machine

Specifications Of Thermoforming Machines

|

Sheet Materials |

PP/PS/PET/PLA/PE |

Air Consumption |

4m³/min |

|

Sheet Thickness |

0.2-1.5mm |

Weight |

15500kg |

|

Forming Area |

730*610mm |

Total Installed Power |

185kw |

|

Width Of Sheet |

400-800mm |

Heating Power |

140kw |

|

Upper Forming Depth |

100mm |

Feeding Motor |

4.4kw |

|

Bottom Forming Depth |

130mm |

Control Forming Plug Motor Power |

4.4kw |

|

Max Speed |

45moulds/min |

Stacking Motor |

1.8kw |

|

The Longest Knife |

10m |

Winding Waste Of Edge Sheet Motor Power |

0.4kw |

|

Dimension |

12785*2350*2700mm |

Forming Motor |

5.5kw*2 |

|

Forming clamping force |

750kn |

Cutting Motor |

5.5kw*2 |

|

Punching clamping force |

750kn |

Punching Motor |

5.5kw*2 |

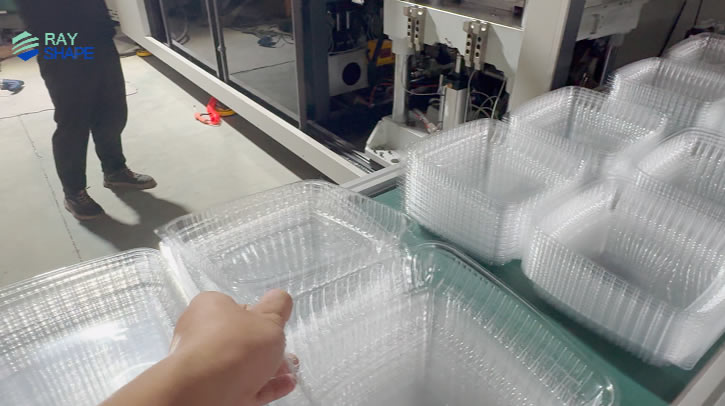

Advantages Of Plastic Thermoforming Machines

Loading sheet part

Load automatically, lower human resource cost.

Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Max undertake roll of sheet

Weight:600kg, Diameter 800mm.

Feeding sheet part

Automatic feeding reduces human resource costs.

Actively transport the sheet and reduce the load on the conveying servo motor.

Cleverly control the proximity switch to prevent the sheet from falling too quickly during transportation.

Human-machine interface

Controlled by microcomputer and programmable controller (PLC), all action programs can be operated through the human-machine interface, simple and convenient, 15-inch touch screen.

Heater

1. Vacuum insulation cotton is installed in the heater, which has a fast reaction speed, short processing time and energy saving.

2. The furnace body is divided into two layers, the layout of the heating tiles is optimized, so that the plate is heated evenly.

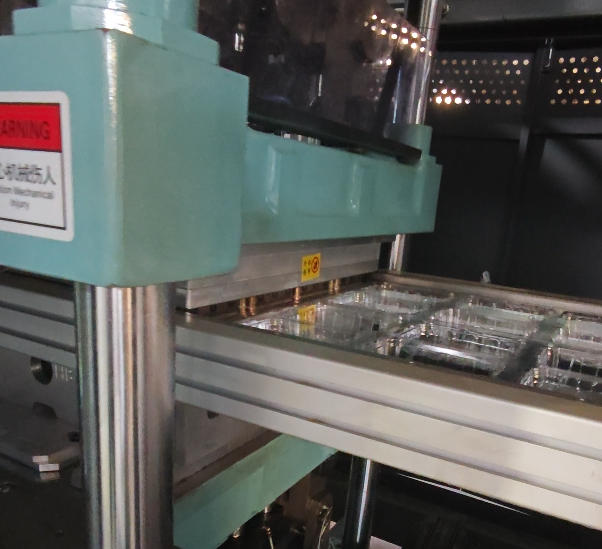

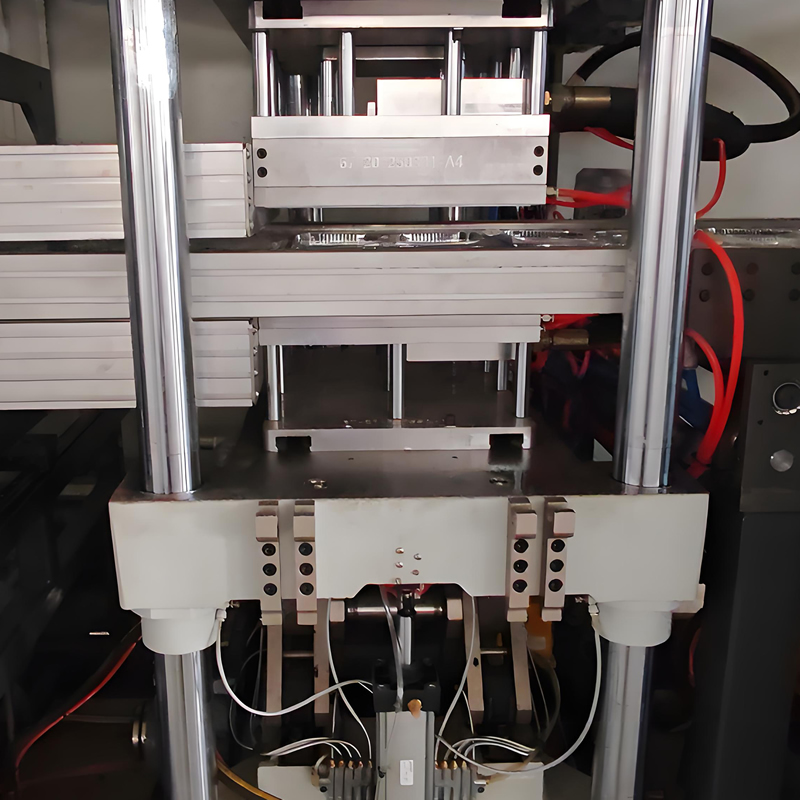

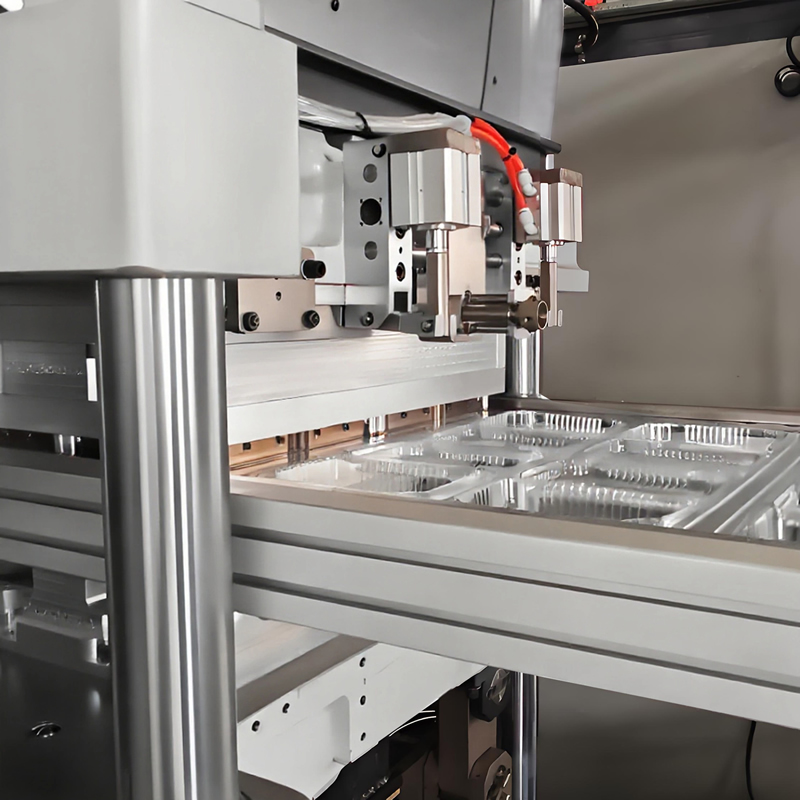

Molding station

1. Mold changing auxiliary mechanism, using sliding guide rails and support rods to achieve fast mold change, saving time and effort.

2. Adopting high-power servo motor drive, high precision, high efficiency and low noise.

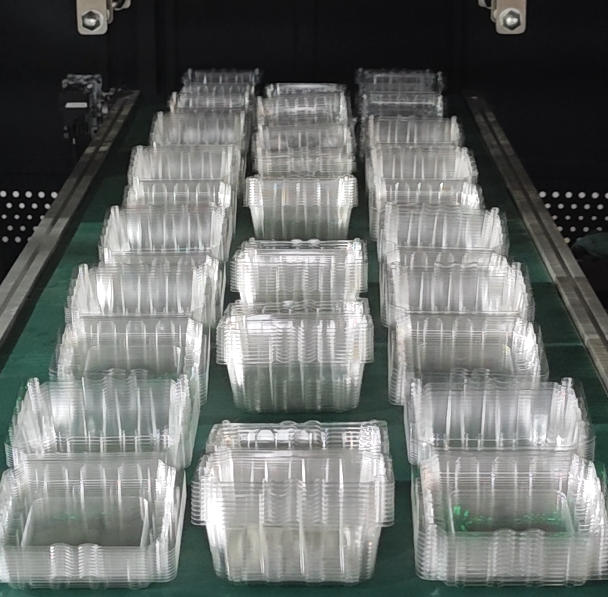

Molding mold

The working principle is a combination of positive and negative pressure, and some nylon plugs are used to assist stretching in the mold to make it have stronger molding ability.

There is cooling water in the mold cavity to speed up the cooling speed and make demolding easier.

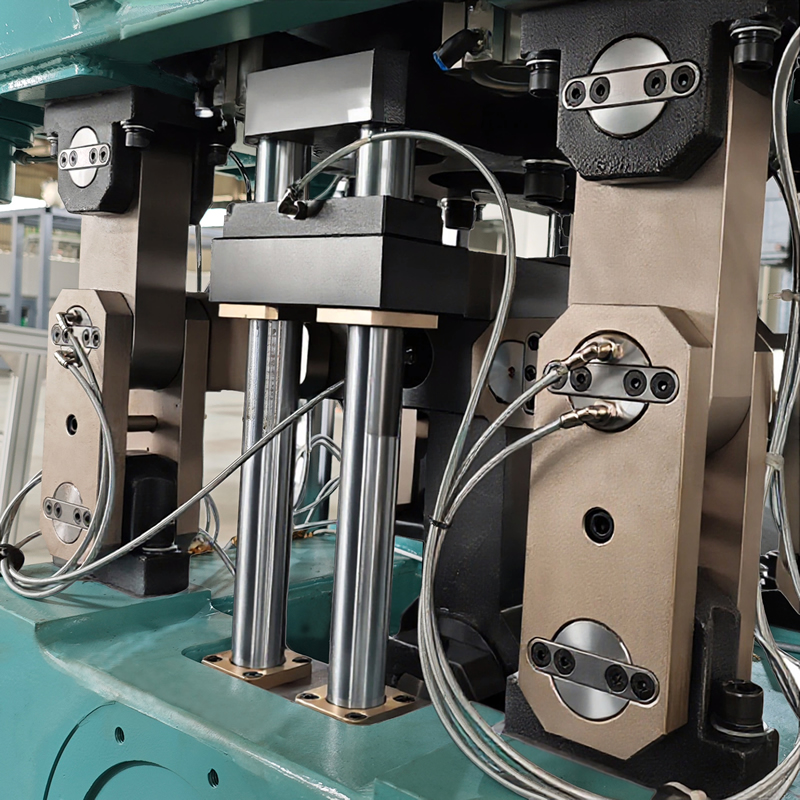

Guide head structure

The workstation is supported by four columns (45# steel, hard chrome plated).

The integrated mold table (QT-600 steel) is made by a high-precision CNC milling machine. Therefore, it is wear-resistant, stable, and accurate, which prolongs the service life of the equipment.

A five-point-connecting-rod structure

This structure design provides more stable operation and faster speed.

Mold change structure

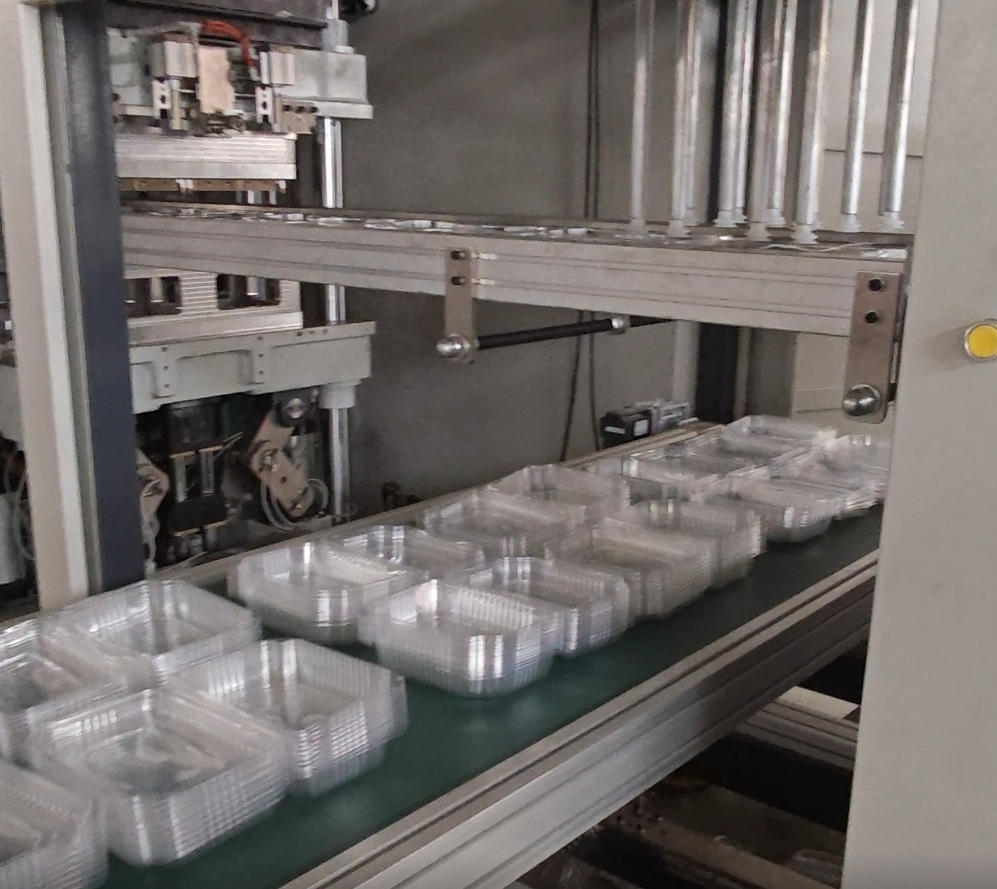

The punching hole station has the same mold changing structure as the cutting station.Greatly reduce mold change time and labor costs, improve production efficiency and safety factor, and provide convenience for your diversified product chain.

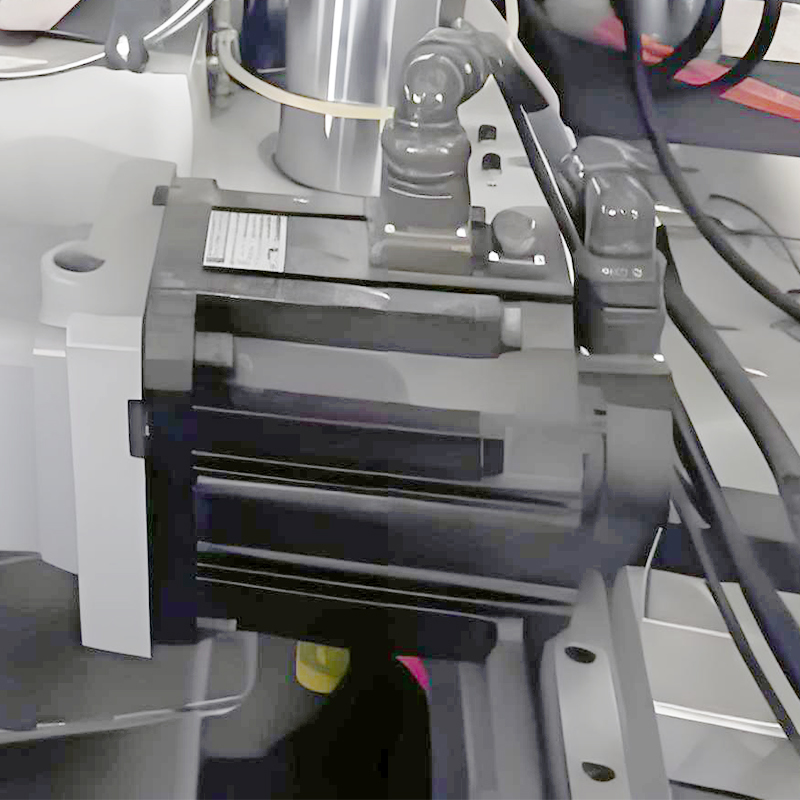

Servo motor

The station mold closing, forming auxiliary stretching, and pull-tab parts are all driven by servo motors, which have fast speed, low noise, high precision, and high efficiency.

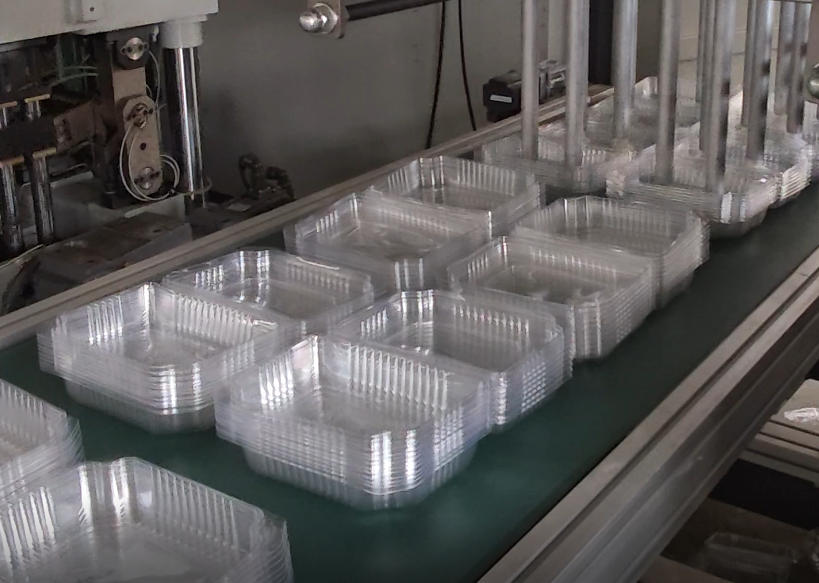

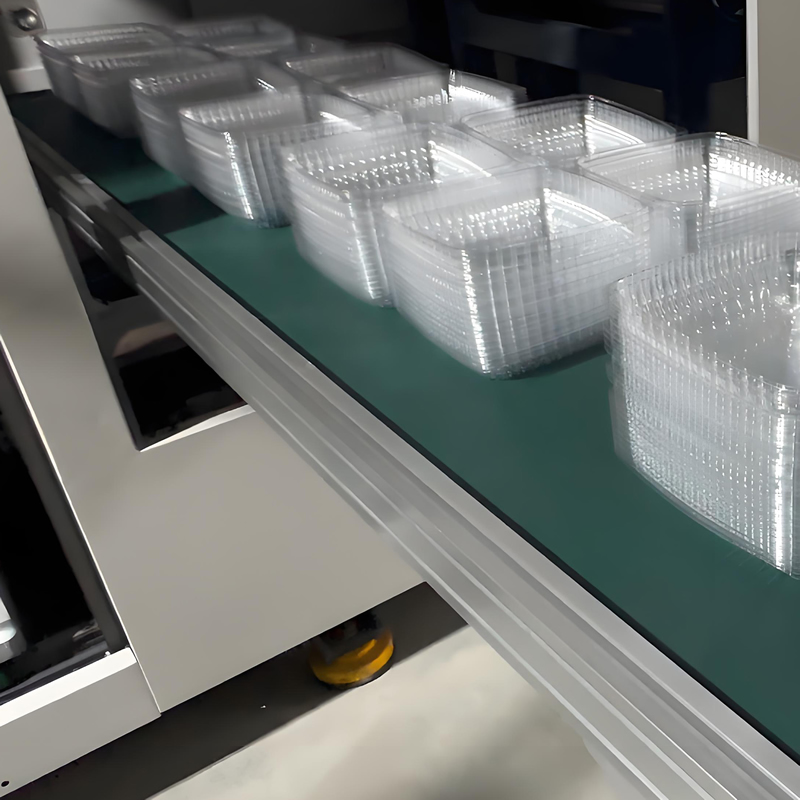

Servo-controlled conveyor belt

Set conveyor belt parameters directly on the operation screen.

Freely adjust and control conveying length and speed.

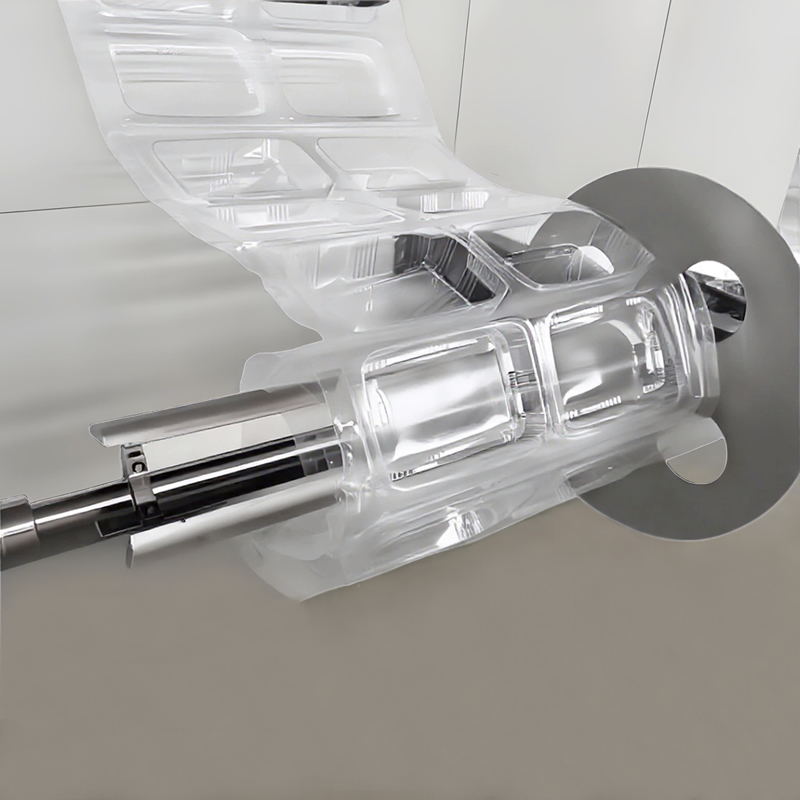

Rewinding waste of edge sheet

Our multi-station thermoformers feature a winding unit with torque motor to efficiently collect the offcuts and wind them into a roll with one side retractable, which can be conveniently removed at the end of production.

This advanced waste management system improves operating efficiency and cleanliness, making multi-station thermoformers ideal for high-quality and sustainable production.

Thermoforming Machine Video

Thermoforming Machine News

Leading Plastic Thermoforming Machine Enterprise in Binhai New Area

Wenzhou Rayshape Machinery Co., Ltd., located in the Binhai New Area of Wenzhou, is a leading enterprise in the production of the Plastic Thermoforming Machine. As a key subsidiary of the Elemotion...

High Volume Food Box Machine for Professional Catering

The professional catering industry requires the high-volume output of the Food Box Machine from Wenzhou Rayshape Machinery Co., Ltd. As part of the Elemotion Group, we are based in Wenzhou and spec...

Automatic Plastic Box Making Machine for Global Supply Chains

Global supply chains demand the efficiency of the Automatic Plastic Box Making Machine from Wenzhou Rayshape Machinery Co., Ltd. A subsidiary of Elemotion Group, we are located at No. 19, East Sect...

BOPS and HIPS Compatible Plastic Container Making Machine

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, offers a Plastic Container Making Machine that is fully compatible with BOPS and HIPS. Located in the coastal Binhai New Area ...

PP Plastic Thermoforming Machine Stability for Microwaveable Trays

Microwaveable trays require the stability of the PP Plastic Thermoforming Machine from Wenzhou Rayshape Machinery Co., Ltd. As part of Elemotion Group, our company in Wenzhou focuses on high-end au...

Advanced Plastic lid forming machine for High Clarity PET

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, provides an Advanced Plastic lid forming machine for high-clarity PET packaging. Located at No. 19, East Section of Pinghai Av...

Multi Station Plastic Thermoforming Equipment for Reliable Output

Reliability is the hallmark of the Multi Station Plastic Thermoforming Equipment from Wenzhou Rayshape Machinery Co., Ltd. A member of the Elemotion Group, our company is based in Pingyang County, ...

Plastic Box Forming Machine for Retail and Electronic Protection

Retail and electronic protection require high-quality packaging, and the Plastic Box Forming Machine from Wenzhou Rayshape Machinery Co., Ltd. is the perfect solution. As a subsidiary of Elemotion ...

Fully Automatic Thermoforming Machine Innovation by Rayshape

Wenzhou Rayshape Machinery Co., Ltd., a key subsidiary of the Elemotion Group, is leading the industry with the Fully Automatic Thermoforming Machine. Based at No. 19, East Section of Pinghai Avenu...

Bowl Making Machine Performance and Reliable Production Output

Wenzhou Rayshape Machinery Co., Ltd., a member of the Elemotion Group, offers a high-performance Bowl Making Machine designed for the food service industry. Located in the Binhai New Area of Wenzho...

Precision Cup Making Machine for Fast Food Beverage Industry

The fast food beverage industry demands high-speed precision, and the Cup Making Machine from Wenzhou Rayshape Machinery Co., Ltd. delivers exactly that. As a subsidiary of Elemotion Group in Wenzh...

Energy Efficient Plastic Thermoforming Equipment for Eco Friendly Trays

Wenzhou Rayshape Machinery Co., Ltd., part of the Elemotion Group, is committed to green manufacturing with our Energy Efficient Plastic Thermoforming Equipment. Based in Wenzhou, we specialize in ...

Versatile Plastic Forming Machine for PVC and HIPS Materials

The Versatile Plastic forming machine from Wenzhou Rayshape Machinery Co., Ltd. is designed to handle the diverse material requirements of modern packaging. As a subsidiary of Elemotion Group, we a...

High Performance Plastic Box Making Machine with Software Control

Wenzhou Rayshape Machinery Co., Ltd., a subsidiary of Elemotion Group, offers a High Performance Plastic Box Making Machine featuring advanced software control. Located at No. 19, East Section of P...

Plastic Container Machine Efficiency for Polypropylene Packaging

Polypropylene (PP) packaging is essential for heat-resistant food containers, and the Plastic Container Machine from Wenzhou Rayshape Machinery Co., Ltd. is optimized for this material. A proud sub...

Durable Vacuum Forming Machine for Industrial Plastic Applications

Industrial plastic applications require the durability and precision of the Vacuum Forming Machine from Wenzhou Rayshape Machinery Co., Ltd. As a subsidiary of Elemotion Group, we are located in th...

Fruit Box Making Machine for Global Agricultural Logistics

The global agricultural logistics sector relies on high-quality packaging, and the Fruit box making machine from Wenzhou Rayshape Machinery Co., Ltd. is the industry standard. As a subsidiary of El...

Plastic Sheet Extruder Integration with Thermoforming Equipment

For a complete production solution, Wenzhou Rayshape Machinery Co., Ltd. offers the Plastic Sheet Extruder designed to work seamlessly with our thermoforming equipment. Based in Wenzhou and part of...

language

language

English

English

Русский

Русский

España

España

Français

Français

عربي

عربي

中文版

中文版