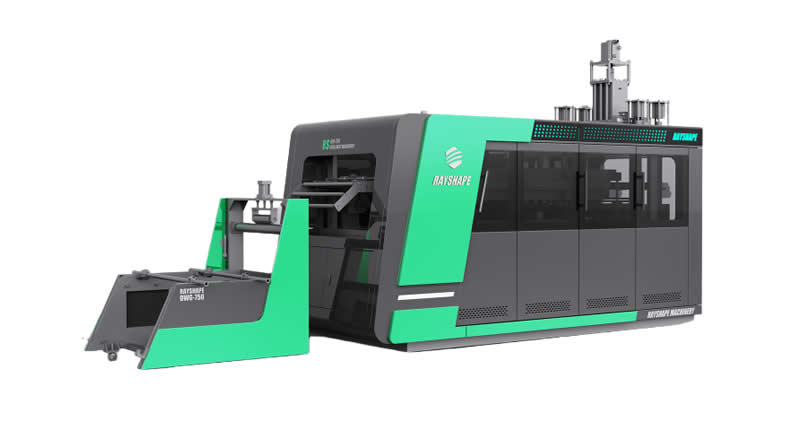

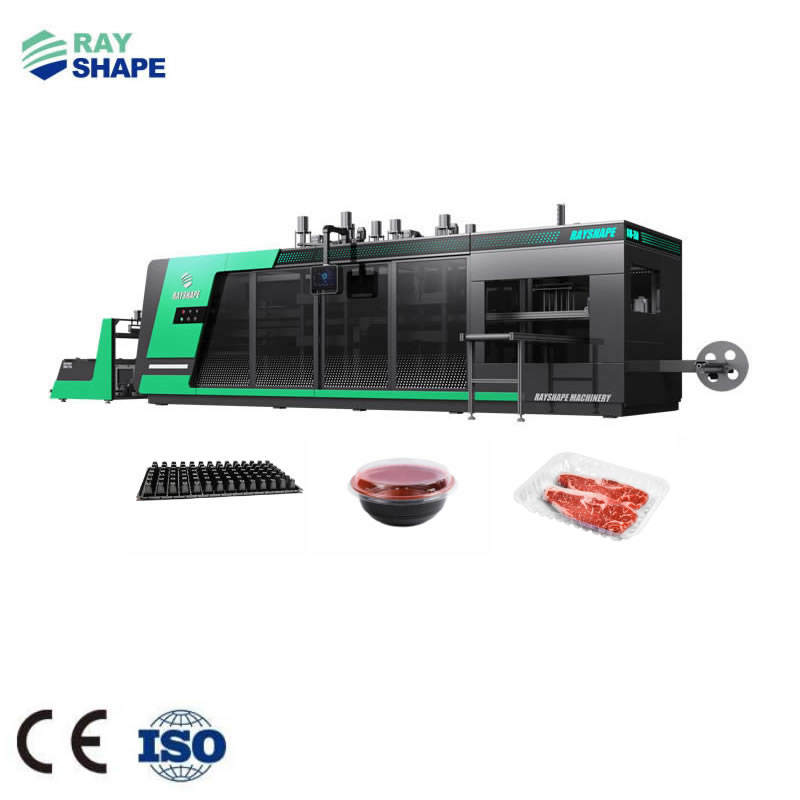

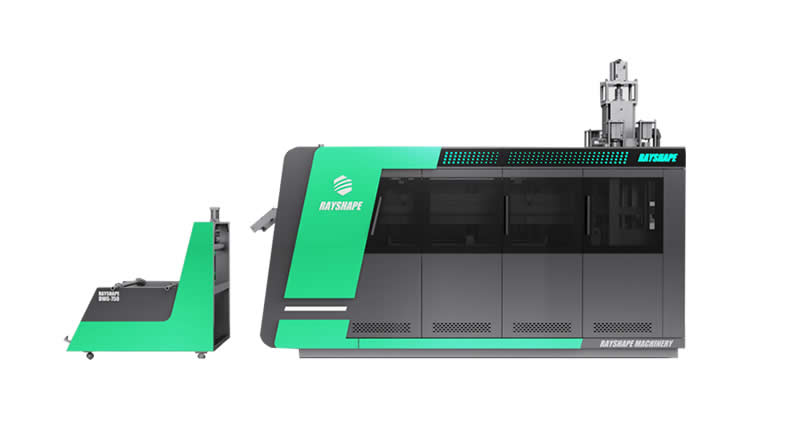

Plastic Cup Making Machine

Model: RSC-800-500

RS-800-500 is a Plastic Cup Making Machine. It uses internationally advanced plastic sheet forming technology. It is a plastic sheet forming equipm...

RS-800-500 is a new generation full servo plastic thermoforming machine. It uses internationally advanced plastic sheet forming technology. It is a plastic sheet forming equipment that integrates mechanical, pneumatic and electrical integrated design. It can automatically complete all actions such as loading, feeding, heating, forming and cutting. Compared with hydraulic drive, this machine has more stable forming, faster speed and cleaner production.

It is suitable for processing different materials, such as A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, PVC and barrier materials, and is suitable for the production of various beverage cups, coffee cups, milk cups, water cups, bowls, boxes and other plastic products.

1. High degree of standardization, complete functions, safe, efficient, energy-saving and hygienic.

2. It integrates mechanical, pneumatic and electrical integration, and is controlled by microcomputer and programmable controller (PLC).

3. Easy-to-operate human-machine interface, and has the function of remote connection.

4. Electric lifting, double-station large-diameter unwinding, allowing a single person to load coils weighing up to 600KG.

5. Servo feeding, stepless adjustment of sheet length, high speed, accuracy and stability.

6. The upper and lower electric heating furnaces are used for 6-7 heating stages and protection to reduce the impact of air convection on temperature, ensuring stable product molding. It only takes 3 minutes to heat from 0 to 400 degrees, improving production efficiency. The electric heating furnace can be automatically removed.

7. The quick mold change system can conveniently, quickly, accurately and safely change molds, reduce machine downtime, reduce labor waste, and improve production efficiency.

8. The mold opening and closing by servo motor, with high precision, low wear, fast speed and low noise. Each station is supported by four columns, combined with a five-point structural connecting rod, which has good stability.

9. Positive pressure forming ensures uniform thickness, full shapes, and sharp corners.

10. The chain frame features a fast cooling and wear-resistant design.

11. The cup blowing system offers adjustable blowing angle and air volume.

12. A servo motor chain drive automatically extends the track to prevent sheet sagging, ensuring stable, precise, and smooth sheet feeding.

13. Combined with the edge material winding device, the entire production process is clean, without burrs and waste.

14. The design of the electrical cabinet is simple and refreshing, simplifying the machine assembly and wiring installation process.

|

Sheet Materials |

PP/PS/PET/PLA/PE/CPET |

Air Consumption |

4m³/min |

|

Sheet Thickness |

0.2-2.5mm |

Weight |

7500kg |

|

Forming Area |

780*480mm |

Total Installed Power |

150KW |

|

Width Of Sheet |

400-850mm |

Heating Power |

122kw |

|

Max Speed |

35moulds/min |

Feeding Motor |

4.4kw |

|

The Longest Knife |

12m |

Control Forming Plug Motor Power |

5.5kw |

|

Dimension |

4500*2000*2600mm |

Winding Waste Of Edge Sheet Motor Power |

0.4kw |

|

Forming clamping force |

1100kn |

Forming Motor |

15kw |

|

Max. Forming Depth |

≤180mm by blowing |

Machine Travel |

≤220mm |

Please fill in the following information

Model: RSC-800-500

RS-800-500 is a Plastic Cup Making Machine. It uses internationally advanced plastic sheet forming technology. It is a plastic sheet forming equipm...

Model: RSC-800-500

For manufacturers of disposable food-grade plastic bowls, reliability, safety, and efficiency are non-negotiable—and the RS-800-500 Plastic Bowl Ma...

Model: RSC-800-500

RS-800-500 is a new generation disposable cup machine. It uses internationally advanced plastic sheet forming technology. It is a plastic sheet for...

Model: RSC-800-500

As the disposable tableware industry evolves, manufacturers demand more advanced, reliable equipment—and the RS-800-500 Plastic Bowl Making Machine...

The high-speed cup production line integrates forming, printing, and stacking to deliver finished cups at unprecedented rates (up to 150 cups/minute). It targets beverage giants and events, reducing l...

In the food, beverage, and pharmaceutical industries, a plastic cap's quality is paramount for product integrity and consumer safety. Meeting this demand for precision and reliability requires special...

The cup making machine is a cornerstone of the food service industry, designed to produce disposable plastic or paper cups at high volumes. It automates processes like sheet feeding, heating, forming,...

Introduction to Wenzhou Rayshape Machinery Co., Ltd. Nestled in the vibrant coastal city of Pingyang County, Wenzhou, Zhejiang Province, at No. 19, East Section of Pinghai Avenue, Binhai New ...

Wenzhou Rayshape Machinery Co., Ltd. is a trusted name in the manufacturing of high-quality Cup Making Machines and Plastic Thermoforming Machines, delivering innovative solutions to meet the diverse ...

Modern cup making machines achieve unprecedented throughput rates of 80 cups/second through synchronized 32-station rotary systems processing PP, PET and PLA sheets from 200-1200 thickness. Material d...

The bowl making machine revolutionizes the production of disposable bowls for food packaging, offering high-speed automation to meet rising demand in takeout and retail sectors. It shapes heated plast...

Precision in Production: Rayshape’s Plastic Cup Making Machine Plastic cups, vital to the food and beverage industry, are crafted with precision using advanced machinery. Wenzhou Rayshape Mac...

Contemporary bowl making machines handle increasingly diverse material portfolios from PS and PP to cellulose-reinforced biopolymers at 60 bowls/minute with precision heating profiles spanning 120-220...

In the dynamic world of consumer goods, plastic cups are an essential part of daily life, serving coffee shops, fast-food chains, supermarkets, and events. The demand for high-quality, durable, and...