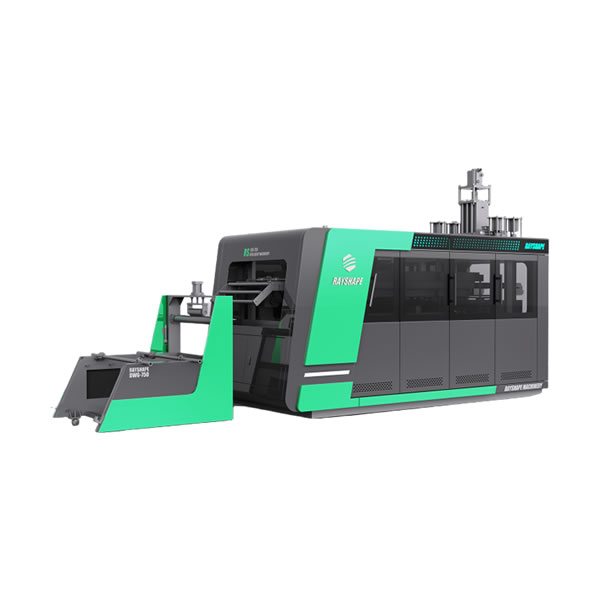

Automatic Thermoforming Machine

RS series automatic thermoforming machine

Multifunctional thermoforming machine

RS Series Plastic Cap Forming Machine

Choosing the Right Cup Making Machine for Beverage Packaging

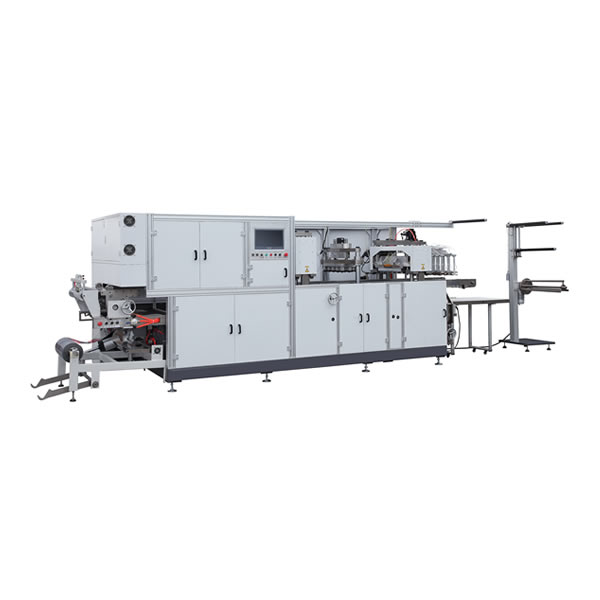

Other Thermoforming Machine

ermoforming Machine Engineering Advancements

Modern thermoforming machines represent the pinnacle of industrial efficiency with servo-electric drive systems reducing energy consumption by 35% compared to hydraulic alternatives. These sophisticat...

Ruisu Machinery, the world's worry-free thermoforming partner!

Reliable products: RS series thermoforming machine + extruder, years of optimization, patented quality, help efficient production. Global response: The marketing network covers 60+ countries, no m...

Advanced Features in Modern Plastic Thermoforming Machine

The plastic thermoforming machine has evolved to address diverse industrial needs by focusing on precision and efficiency. Unlike standard thermoformers, it specifically handles thermoplastics like po...

Efficient Operation of a Blister Forming Machine

A blister forming machine excels in producing airtight packaging for tablets, capsules, or small consumer items. It works by heating a plastic sheet, forming it into cavities (blisters) using vacuum s...

Plastic the world, create unlimited! Ruisu thermoforming equipment is widely used

Core equipment: Fully automatic thermoforming machine, multi-station machine, capping machine, multi-function machine to meet diversified molding needs. Source support: RS series single/double-layer,...

Professional automatic thermoforming machine manufacturer

Wenzhou Ruisu Machinery Co., Ltd. is not only an equipment manufacturer, but also a trusted smart manufacturing partner and solid backing for global customers, sending precision machinery from Pingyan...

Understanding the Basics of a Thermoforming Machine

A thermoforming machine is a pivotal tool in the packaging industry, used to shape plastic sheets into various forms by heating them until pliable and then molding them using vacuum, pressure, or mech...

Innovative plastic molding machines drive future manufacturing

In the wave of global manufacturing intelligence and customization, plastic thermoforming technology plays a vital role. Rooted in Pingyang, Wenzhou, Zhejiang, Wenzhou Ruisu Machinery Co., Ltd. has be...

Professional thermoforming equipment helps you win efficiently

Focus on thermoforming: Provide mature equipment such as fully automatic multi-station thermoforming machines, RS series main machines, multi-function machines, capping machines, etc. More complete s...

Plastic Thermoforming Machine Sustainability Innovations

Leading plastic thermoforming machine manufacturers now integrate circular economy solutions directly into production platforms. Patented closed-loop regrind systems automatically reintroduce 98% of i...

Thermoforming Machine: The Backbone of Modern Packaging

The thermoforming machine stands as a cornerstone in contemporary manufacturing, transforming plastic sheets into precise 3D shapes through controlled heating and forming processes. This equipment emp...

A leading force in the field of plastic thermoforming

In the rapidly developing modern manufacturing industry, plastic thermoforming technology has become an indispensable part of packaging, food, medicine, electronics and other industries with its hi...

language

language